filmov

tv

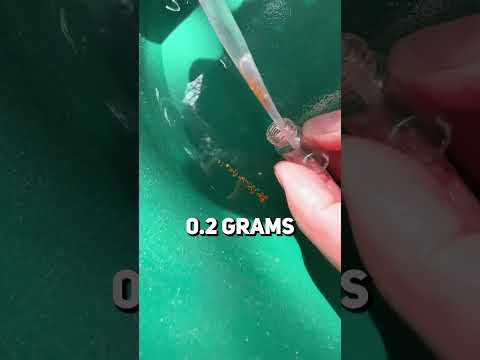

Gold Smelting Test! Determining the Best Gold Recovery Flux

Показать описание

In this video, we test out various gold smelting fluxes to determine which is the best for gold recovery. We will be using different fluxes to melt down gold concentrate and see which yields the highest gold recovery. We will also discuss the different types of fluxes, their properties, and their impact on the smelting process.

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Filming Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

Keywords: gold smelting, gold recovery, smelting fluxes, fluxes for gold, gold concentrate, melting gold, gold mining

Tags: #goldsmelting #goldrecovery #smeltingfluxes #fluxesforgold #goldconcentrate #meltinggold #goldmining

For more info please email or call:

Phone: 360-595-4445

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Filming Equipment:

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

Keywords: gold smelting, gold recovery, smelting fluxes, fluxes for gold, gold concentrate, melting gold, gold mining

Tags: #goldsmelting #goldrecovery #smeltingfluxes #fluxesforgold #goldconcentrate #meltinggold #goldmining

For more info please email or call:

Phone: 360-595-4445

Комментарии

0:15:19

0:15:19

0:00:23

0:00:23

0:00:47

0:00:47

0:30:41

0:30:41

0:00:17

0:00:17

0:00:13

0:00:13

0:01:00

0:01:00

0:00:52

0:00:52

![[Part 2] He](https://i.ytimg.com/vi/pb2ram1kTLY/hqdefault.jpg) 8:34:23

8:34:23

0:00:58

0:00:58

0:18:55

0:18:55

0:09:18

0:09:18

0:01:01

0:01:01

0:00:58

0:00:58

0:00:22

0:00:22

0:00:14

0:00:14

0:00:11

0:00:11

0:00:29

0:00:29

0:00:55

0:00:55

0:00:15

0:00:15

0:00:36

0:00:36

0:00:14

0:00:14

0:00:20

0:00:20

0:00:28

0:00:28