filmov

tv

Capacitor and Hard Start Myths Busted

Показать описание

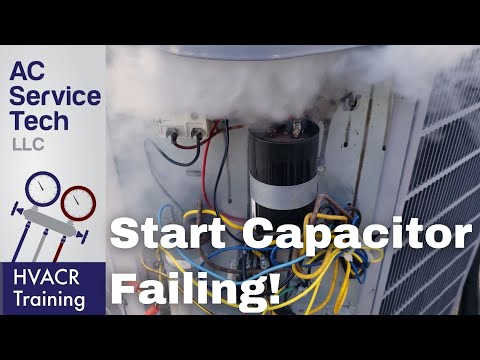

Bryan teaches the Kalos techs all about capacitors, including how they look on diagrams, why they fail, and how to handle them on service calls. He also gets some capacitor and hard start kit myths busted.

Even though we may imagine that current travels across the capacitor, the electrons DON'T travel through the capacitor. Capacitors don't "boost" voltage or current, either; the microfarad rating is actually more likely to reduce or restrict the amount of current that travels through the start winding.

It may be helpful to view the capacitor as a balloon or membrane that stores and releases electricity. As the voltage changes via alternating current (60 times per second for 60 Hz, 50 times per second for 50 Hz), we measure its average via the root mean square (RMS). So, the capacitor charges (through the start winding) and discharges 60 times per second from the same way it came. Capacitors have attractive forces due to the high surface area between the two plates; there is a large sheet of plastic with metal rolled into the capacitor.

You can also think of a capacitor as a third hand to help spin a motor; when we spin wheels with our hands, we apply directional force instead of horizontal force. The legs of power act kind of like sources of horizontal forces, and the capacitor acts like a hand to begin spinning the motor.

Three-phase equipment and ECMs don't require a capacitor because there are already three "hands" spinning the motor without help. On single-phase equipment, the start winding always has current running through it, not just on startup, even though we need another "hand" to help start the motor. That's why we have run capacitors.

If the run capacitor is too small, the compressor might not start and will get hotter because the run capacitor generates heat in the run winding (not the start winding). When the rotor stays locked for any reason, including an undersized capacitor, the amp draw stays high until the compressor goes out on thermal overload. If the run capacitor completely fails, nothing happens on the start winding; no current moves through it whatsoever. A failed start winding may happen if the capacitor is wired in incorrectly, if the capacitor is too large, or if the hard start kit presents problems. So, be sure to do a thorough visual inspection of the capacitor and any other accessories.

We need to be careful when using hard start kits; they don't add a phase shift but give us more current to hit the start winding. However, the start winding isn't designed to handle full current all the time; the hard start kit needs to be able to shut off or take itself out of the circuit, usually via a potential relay. The best hard start kit is almost always the OEM hard start kit, but aftermarket kits are acceptable for temporary solutions or when the unit lacks a factory recommendation. It's also worth noting that capacitors can indeed weaken over time without failing completely.

Incorrect capacitor sizing is common, especially after capacitor or compressor replacements. Sometimes, technicians accidentally install a new run capacitor of the wrong size. In other cases, a new compressor may require a different capacitor size than the previous one; we can't just assume that the new compressor will have the exact same requirements as the previous one.

Even though we may imagine that current travels across the capacitor, the electrons DON'T travel through the capacitor. Capacitors don't "boost" voltage or current, either; the microfarad rating is actually more likely to reduce or restrict the amount of current that travels through the start winding.

It may be helpful to view the capacitor as a balloon or membrane that stores and releases electricity. As the voltage changes via alternating current (60 times per second for 60 Hz, 50 times per second for 50 Hz), we measure its average via the root mean square (RMS). So, the capacitor charges (through the start winding) and discharges 60 times per second from the same way it came. Capacitors have attractive forces due to the high surface area between the two plates; there is a large sheet of plastic with metal rolled into the capacitor.

You can also think of a capacitor as a third hand to help spin a motor; when we spin wheels with our hands, we apply directional force instead of horizontal force. The legs of power act kind of like sources of horizontal forces, and the capacitor acts like a hand to begin spinning the motor.

Three-phase equipment and ECMs don't require a capacitor because there are already three "hands" spinning the motor without help. On single-phase equipment, the start winding always has current running through it, not just on startup, even though we need another "hand" to help start the motor. That's why we have run capacitors.

If the run capacitor is too small, the compressor might not start and will get hotter because the run capacitor generates heat in the run winding (not the start winding). When the rotor stays locked for any reason, including an undersized capacitor, the amp draw stays high until the compressor goes out on thermal overload. If the run capacitor completely fails, nothing happens on the start winding; no current moves through it whatsoever. A failed start winding may happen if the capacitor is wired in incorrectly, if the capacitor is too large, or if the hard start kit presents problems. So, be sure to do a thorough visual inspection of the capacitor and any other accessories.

We need to be careful when using hard start kits; they don't add a phase shift but give us more current to hit the start winding. However, the start winding isn't designed to handle full current all the time; the hard start kit needs to be able to shut off or take itself out of the circuit, usually via a potential relay. The best hard start kit is almost always the OEM hard start kit, but aftermarket kits are acceptable for temporary solutions or when the unit lacks a factory recommendation. It's also worth noting that capacitors can indeed weaken over time without failing completely.

Incorrect capacitor sizing is common, especially after capacitor or compressor replacements. Sometimes, technicians accidentally install a new run capacitor of the wrong size. In other cases, a new compressor may require a different capacitor size than the previous one; we can't just assume that the new compressor will have the exact same requirements as the previous one.

Комментарии

0:28:41

0:28:41

0:05:19

0:05:19

0:04:18

0:04:18

0:02:16

0:02:16

0:06:11

0:06:11

0:04:35

0:04:35

0:03:24

0:03:24

0:09:45

0:09:45

0:04:31

0:04:31

0:05:55

0:05:55

0:02:51

0:02:51

0:20:13

0:20:13

1:19:12

1:19:12

0:09:10

0:09:10

0:13:57

0:13:57

0:09:05

0:09:05

0:03:45

0:03:45

0:10:49

0:10:49

0:08:03

0:08:03

0:03:13

0:03:13

0:03:18

0:03:18

0:05:36

0:05:36

0:02:51

0:02:51

0:10:27

0:10:27