filmov

tv

Toyota Japan Factory Tour - How Japanese cars are made

Показать описание

Toyota Japan Factory Tour - How Japanese cars are made?

Toyota virtual plant tour. 2023 Toyota Crown Cross production.

In this video, we will see every aspect of the five primary processes: stamping, welding, painting, assembly, and inspection.

Now, let's take a look at the production process.

Car manufacturing begins with the creation of doors, hoods and other body parts from large steel plates.

One car can use more than a dozen types of steel plates.

Steel plates are fed into the cutting machine, and punched into different shapes and sizes.

Punched steel plates are pressed into the shape of parts.

And it only takes three seconds, applying 1600 tons of pressure, to make the part.

From stamping, the shaped parts are then put together in welding.

It is here where the beautiful shape of the car comes together.

First, the floor, sides and ceiling are assembled; and as many as 4000 places are welded.

Welding is performed with high precision, because it greatly affects the car's stability.

The doors, hood, and trunk door, among additional parts are attached to the assembled body.

Then, with the human touch and visual check, an inspector confirms quality.

The paint process starts with a wash.

It's an important step for the preceding layers of paint.

The first step - is the primer process.

The body is dipped into a pool of rust-resistant paint.

Then, sealer is applied to steel plate joints.

Next, the collar body is prepared for the middle coat - while it's not seen, it's the care taken for this middle coat, that helps achieve a beautiful color.

The next step - is the top coating process.

Each cars painted one-by-one with its designated color. And finally, a clear coat is sprayed to add luster.

After the car body dries, inspectors rigorously check the painted surface.

The parts installed here, are made with the cooperation of more than 100 parts suppliers in addition to Toyota's own plants.

As many as 3000 parts are installed in a line more than half a mile long.

The doors are temporarily removed, to create space to work.

Interior components, such as electrical wiring, and the ceiling liner, followed by the engine, brakes, and other undercarriage components are installed.

Then bumpers,. tires,. seats,. windshield, and rear glass are installed.

Finally, the doors are reattached.

Once assembled, inspectors confirm, that correct parts are installed on a vehicle.

And then, look for any scratch or dent.

Next, inspectors check and adjust the lighting fixtures, gauges, and any unusual noises, then confirm the gas pedal and brake pedal for effectiveness.

Finally, inspectors confirm there are no oil leaks.

Only vehicles that have passed all of these rigorous inspections are delivered to customers.

All of this is done every day for each and every vehicle, shipped domestically, and throughout the world.

0:12 Stamping

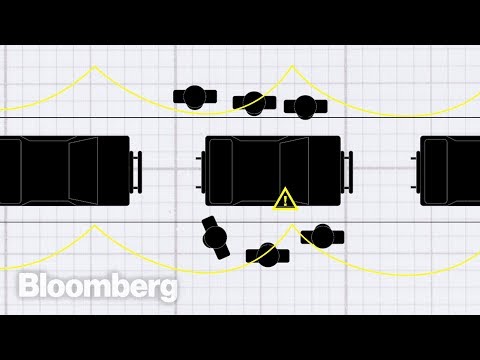

2:15 Welding

4:33 Painting

7:25 Assembly line

11:47 Inspection and quality control

Toyota virtual plant tour. 2023 Toyota Crown Cross production.

In this video, we will see every aspect of the five primary processes: stamping, welding, painting, assembly, and inspection.

Now, let's take a look at the production process.

Car manufacturing begins with the creation of doors, hoods and other body parts from large steel plates.

One car can use more than a dozen types of steel plates.

Steel plates are fed into the cutting machine, and punched into different shapes and sizes.

Punched steel plates are pressed into the shape of parts.

And it only takes three seconds, applying 1600 tons of pressure, to make the part.

From stamping, the shaped parts are then put together in welding.

It is here where the beautiful shape of the car comes together.

First, the floor, sides and ceiling are assembled; and as many as 4000 places are welded.

Welding is performed with high precision, because it greatly affects the car's stability.

The doors, hood, and trunk door, among additional parts are attached to the assembled body.

Then, with the human touch and visual check, an inspector confirms quality.

The paint process starts with a wash.

It's an important step for the preceding layers of paint.

The first step - is the primer process.

The body is dipped into a pool of rust-resistant paint.

Then, sealer is applied to steel plate joints.

Next, the collar body is prepared for the middle coat - while it's not seen, it's the care taken for this middle coat, that helps achieve a beautiful color.

The next step - is the top coating process.

Each cars painted one-by-one with its designated color. And finally, a clear coat is sprayed to add luster.

After the car body dries, inspectors rigorously check the painted surface.

The parts installed here, are made with the cooperation of more than 100 parts suppliers in addition to Toyota's own plants.

As many as 3000 parts are installed in a line more than half a mile long.

The doors are temporarily removed, to create space to work.

Interior components, such as electrical wiring, and the ceiling liner, followed by the engine, brakes, and other undercarriage components are installed.

Then bumpers,. tires,. seats,. windshield, and rear glass are installed.

Finally, the doors are reattached.

Once assembled, inspectors confirm, that correct parts are installed on a vehicle.

And then, look for any scratch or dent.

Next, inspectors check and adjust the lighting fixtures, gauges, and any unusual noises, then confirm the gas pedal and brake pedal for effectiveness.

Finally, inspectors confirm there are no oil leaks.

Only vehicles that have passed all of these rigorous inspections are delivered to customers.

All of this is done every day for each and every vehicle, shipped domestically, and throughout the world.

0:12 Stamping

2:15 Welding

4:33 Painting

7:25 Assembly line

11:47 Inspection and quality control

Комментарии

0:13:43

0:13:43

0:20:02

0:20:02

0:26:00

0:26:00

0:35:24

0:35:24

0:17:23

0:17:23

0:20:25

0:20:25

0:04:52

0:04:52

0:05:27

0:05:27

0:09:04

0:09:04

0:15:12

0:15:12

0:09:59

0:09:59

0:17:31

0:17:31

0:14:55

0:14:55

0:05:50

0:05:50

0:17:04

0:17:04

0:44:23

0:44:23

0:00:46

0:00:46

0:06:35

0:06:35

0:17:47

0:17:47

0:29:37

0:29:37

0:06:36

0:06:36

0:17:22

0:17:22

0:04:57

0:04:57

![[Toyota Production System]](https://i.ytimg.com/vi/TUKpxjAftnk/hqdefault.jpg) 0:01:43

0:01:43