filmov

tv

Refrigeration Cycle | Vapor Compression Cycle | Animation | #Refrigerationcycle #HVAC

Показать описание

The refrigeration cycle is a thermodynamic process that is used in refrigeration and air conditioning systems to transfer heat from a low-temperature region (typically the conditioned space) to a high-temperature region (typically the surroundings). The purpose of the refrigeration cycle is to maintain a lower temperature in a controlled environment by removing heat from that space.

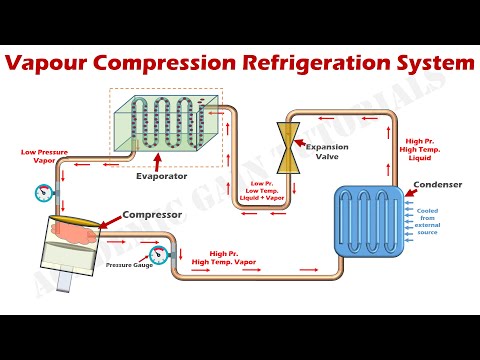

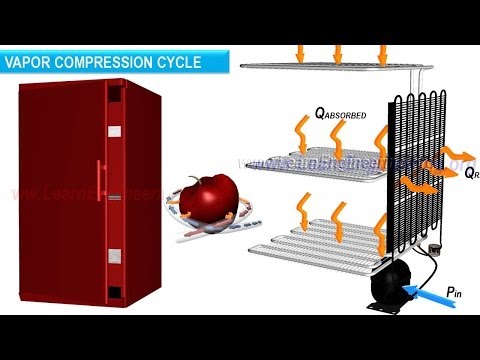

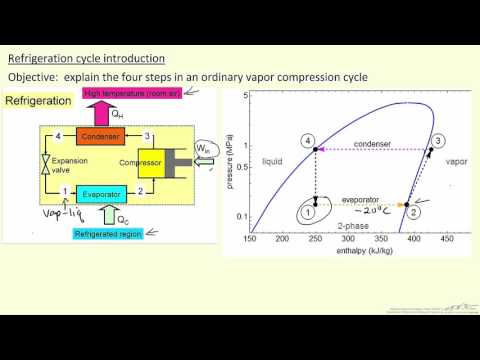

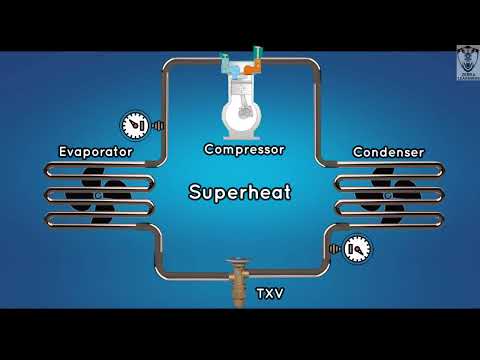

The refrigeration cycle consists of four main components: the compressor, condenser, expansion valve (or throttle valve), and evaporator. These components work together to circulate a refrigerant, which is a fluid with desirable thermodynamic properties for heat transfer.

Here is a brief overview of the four stages of the refrigeration cycle:

Compression: The refrigerant enters the compressor as a low-pressure vapor and is compressed, increasing its temperature and pressure.

Condensation: The high-pressure, high-temperature refrigerant then flows into the condenser, where it releases heat to the surroundings. As a result, the refrigerant condenses into a high-pressure liquid.

Expansion: The high-pressure liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature. This causes the refrigerant to partially vaporize, entering the next stage as a low-pressure mixture of liquid and vapor.

Evaporation: The low-pressure refrigerant mixture enters the evaporator, where it absorbs heat from the conditioned space, causing the remaining liquid to vaporize. The vaporized refrigerant is then drawn back into the compressor, and the cycle repeats.

By continuously circulating the refrigerant through these stages, the refrigeration cycle removes heat from the conditioned space, keeping it cool, while releasing the absorbed heat to the surroundings.

It's important to note that the refrigeration cycle can be modified and optimized for various applications, such as domestic refrigerators, air conditioners, industrial cooling systems, and more. Different refrigerants and system configurations can be utilized based on specific requirements and environmental considerations.

Thank You and Subscribe Our Channel!

The refrigeration cycle consists of four main components: the compressor, condenser, expansion valve (or throttle valve), and evaporator. These components work together to circulate a refrigerant, which is a fluid with desirable thermodynamic properties for heat transfer.

Here is a brief overview of the four stages of the refrigeration cycle:

Compression: The refrigerant enters the compressor as a low-pressure vapor and is compressed, increasing its temperature and pressure.

Condensation: The high-pressure, high-temperature refrigerant then flows into the condenser, where it releases heat to the surroundings. As a result, the refrigerant condenses into a high-pressure liquid.

Expansion: The high-pressure liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature. This causes the refrigerant to partially vaporize, entering the next stage as a low-pressure mixture of liquid and vapor.

Evaporation: The low-pressure refrigerant mixture enters the evaporator, where it absorbs heat from the conditioned space, causing the remaining liquid to vaporize. The vaporized refrigerant is then drawn back into the compressor, and the cycle repeats.

By continuously circulating the refrigerant through these stages, the refrigeration cycle removes heat from the conditioned space, keeping it cool, while releasing the absorbed heat to the surroundings.

It's important to note that the refrigeration cycle can be modified and optimized for various applications, such as domestic refrigerators, air conditioners, industrial cooling systems, and more. Different refrigerants and system configurations can be utilized based on specific requirements and environmental considerations.

Thank You and Subscribe Our Channel!

Комментарии

0:05:13

0:05:13

0:06:09

0:06:09

0:05:29

0:05:29

0:28:06

0:28:06

0:04:19

0:04:19

0:04:35

0:04:35

0:10:36

0:10:36

0:01:54

0:01:54

1:01:35

1:01:35

0:12:44

0:12:44

0:06:35

0:06:35

0:03:53

0:03:53

0:05:36

0:05:36

0:04:20

0:04:20

0:19:57

0:19:57

0:07:46

0:07:46

0:16:27

0:16:27

0:09:35

0:09:35

0:06:40

0:06:40

0:03:35

0:03:35

0:08:18

0:08:18

0:05:44

0:05:44

0:33:39

0:33:39

0:06:04

0:06:04