filmov

tv

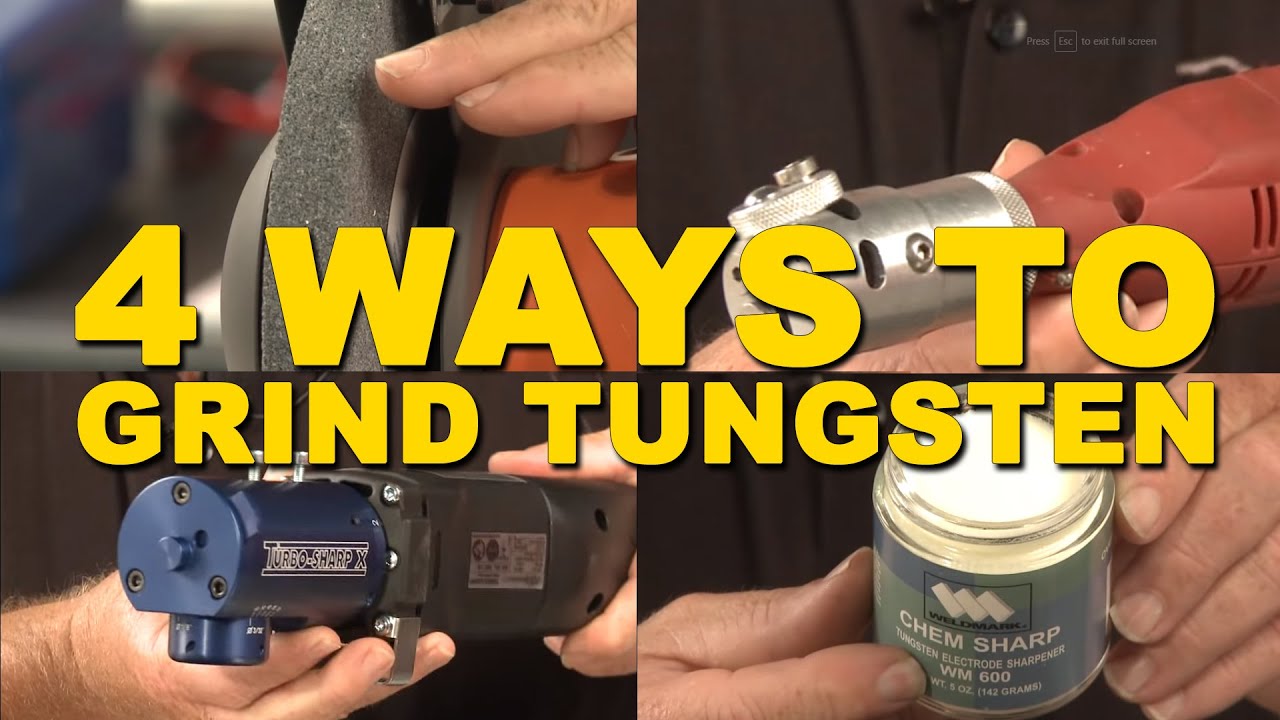

4 Easy Ways to Grind Tungsten for TIG Welding | TIG Time

Показать описание

#welddotcom

In this episode of TIG Time, Wyatt will be demonstrating four ways to effectively grind Tungsten for TIG welding. There are many different ways, but in this episode we tried to pick some ways that will fit everyone's budget. So if you are just getting into welding as a hobby or you are an experienced welder; this episode has something for you.

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

In this episode of TIG Time, Wyatt will be demonstrating four ways to effectively grind Tungsten for TIG welding. There are many different ways, but in this episode we tried to pick some ways that will fit everyone's budget. So if you are just getting into welding as a hobby or you are an experienced welder; this episode has something for you.

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

Комментарии

0:10:16

0:10:16

0:00:15

0:00:15

0:00:21

0:00:21

0:00:22

0:00:22

0:03:22

0:03:22

0:00:31

0:00:31

0:00:20

0:00:20

0:00:13

0:00:13

0:00:22

0:00:22

0:00:27

0:00:27

0:00:07

0:00:07

0:00:34

0:00:34

0:00:42

0:00:42

0:00:27

0:00:27

0:00:19

0:00:19

0:00:12

0:00:12

0:00:47

0:00:47

0:00:14

0:00:14

0:00:36

0:00:36

0:00:20

0:00:20

0:00:20

0:00:20

0:00:27

0:00:27

0:00:26

0:00:26

0:00:21

0:00:21