filmov

tv

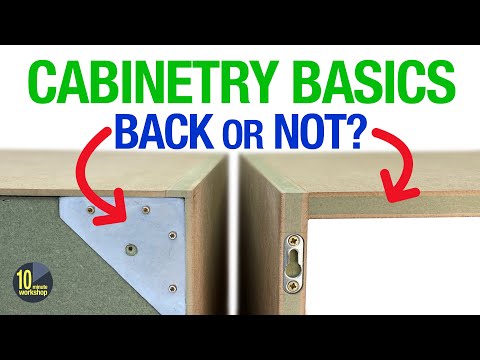

Cabinetry Basics Part 1 [video 435]

Показать описание

I get a lot of questions about cabinet and carcass construction and in this series I aim to answer them all, starting here with the most asked question of all; on a wall-hung cabinet, should the top and base sit within or above, the sides?

+++++++++

**Please note that I am moving away from the legacy member platforms to concentrate on my own memberships at 10MinuteWorkshop Plus; member benefits at Patreon and YTM will be significantly reduced from October 2022.

+++++++++

If you’re looking for a few gift ideas and would like to support the channel then take a look at my Etsy store, my Amazon Affiliate store, or any of the links below.

Connect with me on twitter @10minuteshop

Connect with me on Instagram @10minuteworkshop

+++++++

As an Amazon Associate, I earn from qualifying purchases made through these links.

Wherever possible links are to actual products used, but this is not always possible e.g. some products are not available in the US, so something [similar] has been linked to instead.

++++++++

Mentioned in this video:-

++++++++

Other useful gear…

+++++++++

**Please note that I am moving away from the legacy member platforms to concentrate on my own memberships at 10MinuteWorkshop Plus; member benefits at Patreon and YTM will be significantly reduced from October 2022.

+++++++++

If you’re looking for a few gift ideas and would like to support the channel then take a look at my Etsy store, my Amazon Affiliate store, or any of the links below.

Connect with me on twitter @10minuteshop

Connect with me on Instagram @10minuteworkshop

+++++++

As an Amazon Associate, I earn from qualifying purchases made through these links.

Wherever possible links are to actual products used, but this is not always possible e.g. some products are not available in the US, so something [similar] has been linked to instead.

++++++++

Mentioned in this video:-

++++++++

Other useful gear…

Комментарии

0:08:20

0:08:20

0:11:34

0:11:34

0:16:16

0:16:16

0:12:20

0:12:20

0:20:57

0:20:57

0:00:17

0:00:17

0:07:19

0:07:19

0:00:37

0:00:37

4:32:02

4:32:02

0:05:35

0:05:35

0:16:51

0:16:51

0:21:12

0:21:12

0:00:29

0:00:29

0:18:32

0:18:32

0:01:01

0:01:01

0:04:03

0:04:03

0:00:23

0:00:23

0:00:24

0:00:24

0:10:27

0:10:27

0:00:32

0:00:32

0:00:53

0:00:53

0:00:24

0:00:24

0:00:26

0:00:26

0:00:19

0:00:19