filmov

tv

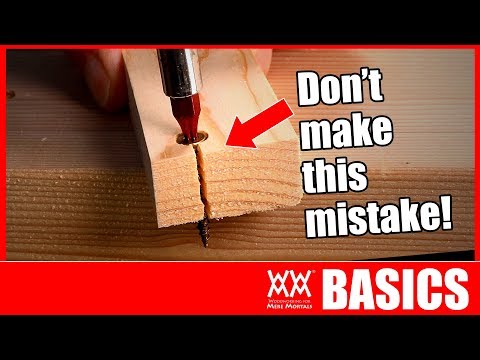

Don't Use Screws That Are TOO LONG or TOO SHORT! (Screw Length/How To Choose The Right Screw Length)

Показать описание

Check Out Our FREE GUIDE: *25 Must-Have Carpentry Tools...Under $25 Each!*

AFFILIATE TOOL LINKS:

Power Pro #9 3" Deck Screws:

Tan Star Drive #8 2" Deck Screws:

WoodPro #9 2-1/2" Construction Screws:

Power Pro #8 1-1/4" Deck Screws:

Dewalt 20v Drill/Driver Kit (Best Seller):

Dewalt Titanium Drill Bit Set (Best Seller):

Dewalt Impact Bit Set 40 pc. (Best Seller):

(These are affiliate links. When you shop through these links, we receive a small commission at NO EXTRA CHARGE TO YOU. We greatly appreciate the support!)

FOLLOW US ON INSTAGRAM:

FOLLOW US ON LINKEDIN:

Don't Use Screws That Are TOO LONG or TOO SHORT! (Screw Length/How To Choose The Right Screw Length)

People often ask how much screw they should use for fastening boards together. Screw length can be a tricky thing to figure out. This short video from The Honest Carpenter will show you a few rules of thumb that can help out in almost any situation.

The screws in this video fall int the "Utility Screw" category, and are "deck screws" in particular. This is a very good, common screw to use for strength in household projects.

#8 is the most common deck screw gauge. But, thicker #9 screws are showing up more frequently on the market as well these days.

If you're connecting two boards through the cross-grain, then you ideally want 1 to 1-1/2" of screw thread in the BOTTOM BOARD.

However, if the bottom board is thinner, like 3/4", then too much screw will punch through the back. In this case, size down to a 1-1/4".

When in doubt, used more fasteners! But be sure to provide them a little spacing--at least 3/4" apart.

When connecting into end grain, you need more screw length, because end grain doesn't hold screws very well. You ideally want 2" of screw thread in the bottom board. So, for 2x4 stock, you want to use a 3-1/2" screw.

However, if your stock is thinner here, like 3/4", then 2" of screw in the bottom board has a higher probability of breaking the wood, or bulging it. You may want to size down to a 2" screw overall.

RULE OF THUMB: In this application, you want 1/3 of the screw in the top board, and about 2/3 in the bottom board.

Thanks for watching!

Be sure to visit us at The Honest Carpenter Website:

Check out our other videos about wood / fasteners:

WHAT IS SPF LUMBER?:

DON'T USE DRYWALL ANCHORS--TRY THIS!:

AFFILIATE TOOL LINKS:

Power Pro #9 3" Deck Screws:

Tan Star Drive #8 2" Deck Screws:

WoodPro #9 2-1/2" Construction Screws:

Power Pro #8 1-1/4" Deck Screws:

Dewalt 20v Drill/Driver Kit (Best Seller):

Dewalt Titanium Drill Bit Set (Best Seller):

Dewalt Impact Bit Set 40 pc. (Best Seller):

(These are affiliate links. When you shop through these links, we receive a small commission at NO EXTRA CHARGE TO YOU. We greatly appreciate the support!)

FOLLOW US ON INSTAGRAM:

FOLLOW US ON LINKEDIN:

Don't Use Screws That Are TOO LONG or TOO SHORT! (Screw Length/How To Choose The Right Screw Length)

People often ask how much screw they should use for fastening boards together. Screw length can be a tricky thing to figure out. This short video from The Honest Carpenter will show you a few rules of thumb that can help out in almost any situation.

The screws in this video fall int the "Utility Screw" category, and are "deck screws" in particular. This is a very good, common screw to use for strength in household projects.

#8 is the most common deck screw gauge. But, thicker #9 screws are showing up more frequently on the market as well these days.

If you're connecting two boards through the cross-grain, then you ideally want 1 to 1-1/2" of screw thread in the BOTTOM BOARD.

However, if the bottom board is thinner, like 3/4", then too much screw will punch through the back. In this case, size down to a 1-1/4".

When in doubt, used more fasteners! But be sure to provide them a little spacing--at least 3/4" apart.

When connecting into end grain, you need more screw length, because end grain doesn't hold screws very well. You ideally want 2" of screw thread in the bottom board. So, for 2x4 stock, you want to use a 3-1/2" screw.

However, if your stock is thinner here, like 3/4", then 2" of screw in the bottom board has a higher probability of breaking the wood, or bulging it. You may want to size down to a 2" screw overall.

RULE OF THUMB: In this application, you want 1/3 of the screw in the top board, and about 2/3 in the bottom board.

Thanks for watching!

Be sure to visit us at The Honest Carpenter Website:

Check out our other videos about wood / fasteners:

WHAT IS SPF LUMBER?:

DON'T USE DRYWALL ANCHORS--TRY THIS!:

Комментарии

0:05:22

0:05:22

0:09:46

0:09:46

0:00:43

0:00:43

0:04:44

0:04:44

0:09:28

0:09:28

0:05:27

0:05:27

0:02:21

0:02:21

0:06:07

0:06:07

0:00:39

0:00:39

0:00:13

0:00:13

0:10:54

0:10:54

0:07:13

0:07:13

0:00:17

0:00:17

0:05:21

0:05:21

0:03:45

0:03:45

0:09:08

0:09:08

0:01:39

0:01:39

0:00:06

0:00:06

0:03:33

0:03:33

0:09:45

0:09:45

0:09:47

0:09:47

0:08:54

0:08:54

0:00:16

0:00:16

0:13:47

0:13:47