filmov

tv

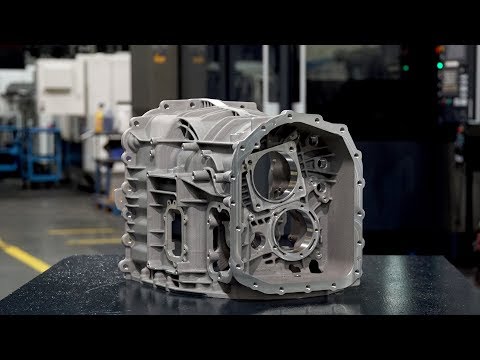

ACTech Prototype Foundry

Показать описание

ACTech operates several melting furnaces for aluminum, iron and steel alloys in its own foundry center. This provides the flexibility to not only realize up to 200 prototype projects at the same time, but also to cast an assembled mold in less than one hour. With the help of the vacuum-supported casting technique, we are able to achieve the low wall thicknesses on prototypes for later pressure die casting. And, with a directional solidification in the sand casting mold, we fulfil even the highest demands of our customers in material properties and structure formation, comparable to die casting. The mechanical properties can be set precisely in the concluding heat treatment.

0:01:53

0:01:53

0:04:26

0:04:26

0:16:48

0:16:48

0:01:01

0:01:01

0:02:38

0:02:38

0:01:08

0:01:08

0:01:26

0:01:26

0:02:34

0:02:34

0:03:03

0:03:03

0:01:28

0:01:28

0:01:00

0:01:00

0:00:33

0:00:33

0:00:52

0:00:52

0:00:56

0:00:56

0:00:42

0:00:42

0:02:20

0:02:20

0:02:05

0:02:05

0:02:07

0:02:07

0:00:26

0:00:26

0:00:40

0:00:40

0:01:04

0:01:04

0:02:08

0:02:08

0:00:27

0:00:27

0:30:48

0:30:48