filmov

tv

Converting Plug In Power Tools To Run On Batteries

Показать описание

Plug your M18 tools into the wall!

Converting Plug In Power Tools To Run On Batteries

Dewalt Hack: Putting a Cord on Cordless Tools...would you or should you?

RYOBI 18V AC Adapter Hack

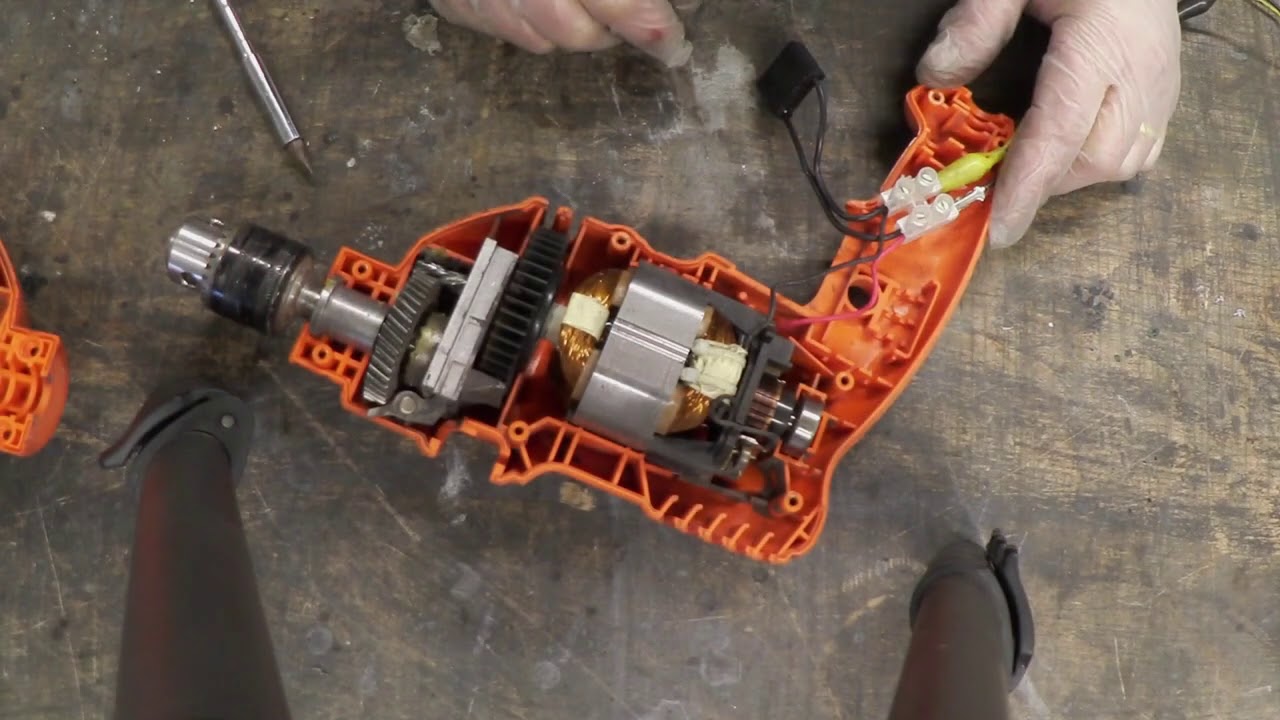

How to convert an angle grinder into a drill

Keep Your Old Power Adapters!!!

Use any brand battery in any power tool 18v-20v DEWALT MILWAUKEE MAKITA PORTER CABLE BOSCH adapters

Milwaukee 1/2-Drive Socket to 1/4-Hex Quick Change Adaptor - Shockwave

Tool box Tour!!!

How to fix a battery #dewalt#batterysave #diy

Battery Adapters for all power tools 18v - 20v Dewalt Milwaukee Makita Bauer Makita

Fixing a dead battery that won’t charge #shoptips #shophacks #batteries #batteryhacks

OBSOLETE Milwaukee M18 Battery YOU Should STOP Buying!

Cord to Cordless Circular Saw Conversion From 100v to 18V

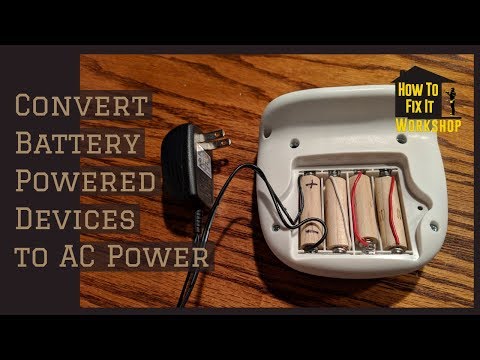

Convert Battery Powered Devices to AC Power

Hack My Dewalt Charger and Make A Multi-Voltage DC Power Supply

Make a Battery Powered device Plug-in compatible

240V DeWalt charger on 110V UK building site voltage doubler rectifier adaptor #electronicscreatos

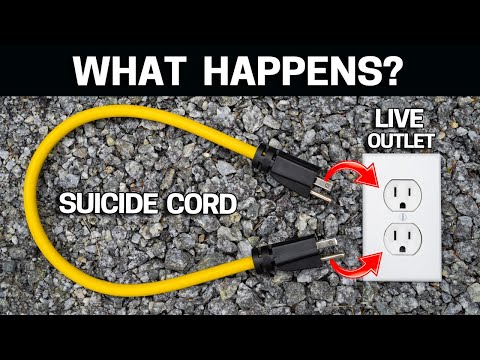

What Happens When You Plug a SUICIDE CORD in a LIVE OUTLET? Do Not Try This Ever

Dual-purpose plug #conversion plug #household high-power plug

Never Replace Batteries Again! Convert Battery Device To Wall Adapter!

How to use 3 Phase Machinery WITHOUT 3 Phase Power!

How To Convert Any 12 Volt Power Tool To A Universal 🔋 🔋 Battery 🔋 🔋

DeWalt 20V DCF921/923 or Milwaukee M12 FUEL Stubby Impact Wrench

Комментарии

0:10:50

0:10:50

0:04:26

0:04:26

0:11:50

0:11:50

0:06:26

0:06:26

0:00:18

0:00:18

0:05:59

0:05:59

0:13:12

0:13:12

0:00:17

0:00:17

0:12:01

0:12:01

0:00:32

0:00:32

0:07:08

0:07:08

0:00:44

0:00:44

0:00:26

0:00:26

0:15:42

0:15:42

0:03:59

0:03:59

0:13:53

0:13:53

0:03:24

0:03:24

0:08:54

0:08:54

0:02:42

0:02:42

0:00:23

0:00:23

0:05:52

0:05:52

0:03:54

0:03:54

0:01:01

0:01:01

0:00:59

0:00:59