filmov

tv

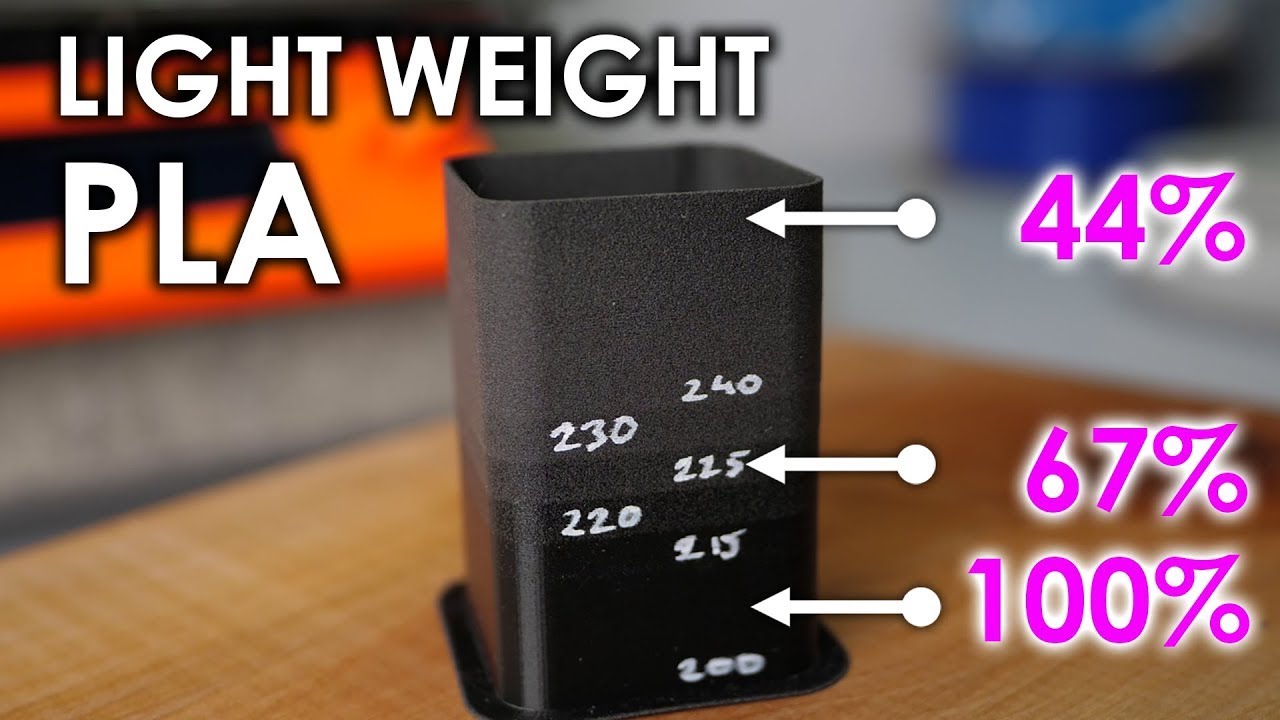

A 4th dimension for 3D prints - Colorfabb Light-Weight, foaming PLA

Показать описание

I can highly recommend "Failure is not an Option" by Gene Kranz!

ColorFabb released 2 new light weight materials based on TPU and PLA. These materials use a blowing agent to create microscopic bubbles in the material during printing and therefore can lower the density by almost 60%. I tested the printability and strength of the LW-PLA at different levels of foaming to see for which applications it might be usable.

The material is available in black and white and sells for $45 a roll.

💚 Support me 💚

Join as a YouTube member!

🤑 Get the materials:

📚Further information:

🖨 Printed models:

🎙Check out my PODCAST with Tom Sanladerer

🎥 Related videos:

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

DISCLAIMER: This video was sponsored by Audible.

ColorFabb released 2 new light weight materials based on TPU and PLA. These materials use a blowing agent to create microscopic bubbles in the material during printing and therefore can lower the density by almost 60%. I tested the printability and strength of the LW-PLA at different levels of foaming to see for which applications it might be usable.

The material is available in black and white and sells for $45 a roll.

💚 Support me 💚

Join as a YouTube member!

🤑 Get the materials:

📚Further information:

🖨 Printed models:

🎙Check out my PODCAST with Tom Sanladerer

🎥 Related videos:

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

DISCLAIMER: This video was sponsored by Audible.

A Beginner's Guide to the Fourth Dimension

4th dimension in 3 minutes.

The Fourth Dimension

What Will You Look Like in 4th Dimensional Space

4th Dimension Explained In 60 Seconds!!

What Will You See In 4th Dimensional Space (3d)

What would a 4D object look like to us?

Tesseract - Hypercube 4th dimension Infinity Mirror Art Sculpture by Nicky Alice

What is the 4th Dimension REALLY? - 4D Golf Devlog #2

No privacy in the 4th dimension

Understanding 4D -- The Tesseract

How many Dimensions are there?

What Does a 4D Ball Look Like in Real Life? Amazing Experiment Shows Spherical Version of Tesseract

Can we move in the 4th dimension?

Type of Shapes 1D 2D 3D 4D 9D #shortvideo #youtubeshorts #drawing #shorts

4th Dimension Explained ► Tesseract Hypercube Visualized More Than 4 Ways

The 4th Dimension Explained (Blueprint for ASCENSION)

Drawing the 4th, 5th, 6th, and 7th dimension

What Will You See in 4th Dimensional Space?

A Journey into the 4th Dimension - Perspective [Part 1]

ONLY 4D People Can SEE This Shape!!!

What the 5th Dimension Looks Like

Exploring other dimensions - Alex Rosenthal and George Zaidan

All 11 dimensions explained 🔥🔥 #shorts

Комментарии

0:06:21

0:06:21

0:02:54

0:02:54

0:00:36

0:00:36

0:07:39

0:07:39

0:01:00

0:01:00

0:20:33

0:20:33

0:00:48

0:00:48

0:00:33

0:00:33

0:07:25

0:07:25

0:00:59

0:00:59

0:03:57

0:03:57

0:00:28

0:00:28

0:07:52

0:07:52

0:00:49

0:00:49

0:00:24

0:00:24

0:10:47

0:10:47

0:10:37

0:10:37

0:03:51

0:03:51

0:12:16

0:12:16

0:12:51

0:12:51

0:01:00

0:01:00

0:00:59

0:00:59

0:04:49

0:04:49

0:00:26

0:00:26