filmov

tv

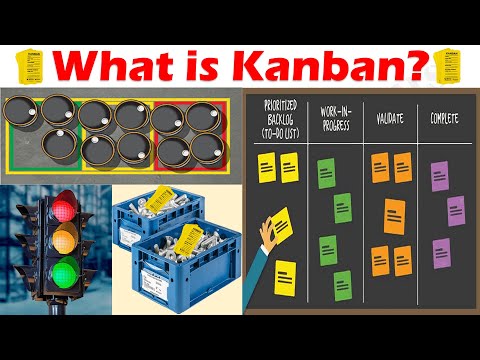

🆕what is kanban in lean manufacturing 🏻 what is kanban system video

Показать описание

Are you looking to more about what is kanban in lean manufacturing and why it is important to understand the kanban concept in ERP?

The video is all about what is kanban in lean manufacturing information but also try to cover the following topics:

-what is kanban system

-lean manufacturing video

-kanban agile

What are Kanban and E-Kanban?

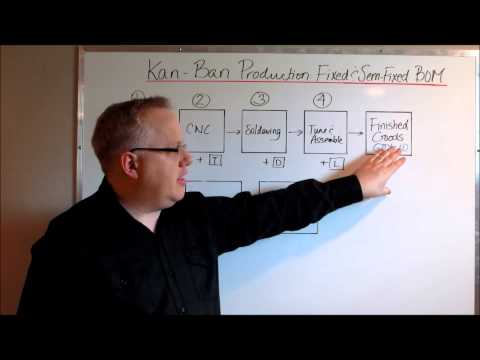

Kanban (signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing.

It was developed by Toyota to improve manufacturing efficiency.

The system takes its name from the cards that track production within a factory.

Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement.

Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps.

One of the main benefits of kanban is to establish an upper limit to work in process inventory to avoid overcapacity.

A kanban system quickly responds to observed demand, in that it is used as a demand signal that immediately travels through the supply chain.

This ensures that intermediate stock held in the supply chain are better managed, and are usually smaller.

Where the supply response is not quick enough to meet actual demand fluctuations, a stock building may be deemed more appropriate and is achieved by placing more kanban in the system.

The kanban card is, in effect, a message that signals a depletion of product, parts, or inventory.

When received, the kanban triggers replenishment of that product, part, or inventory.

Consumption, therefore, drives demand for more production, and the kanban card signals demand for more product—so kanban cards help create a demand-driven system.

Electronic Kanban or E-Kanban differs from traditional kanban in using technology to replace traditional elements like kanban cards with barcodes and electronic messages.

E-kanban systems can be integrated into ERP systems, enabling real-time demand signaling across the supply chain and improved visibility.

So you wish to find out more about what is kanban in lean manufacturing, I did too and here's the outcome.

What is kanban in lean manufacturing interested me so I did some research study and published this to YT .

If you want to learn more about what is kanban system I advise you to take a look at our various other videos :

_________________________

Have I answered all of your concerns about what is kanban in lean manufacturing?

People who searched for what is kanban system likewise searched for lean manufacturing video.

Let us know in the comments if you have any question about E-Kanban or Kanban in ERP and we will be happy to answer.

Do let us know if there is any ERP related topic that you would like us to cover in a video and don't forget to subscribe to our channel, like and share this video^^

The video is all about what is kanban in lean manufacturing information but also try to cover the following topics:

-what is kanban system

-lean manufacturing video

-kanban agile

What are Kanban and E-Kanban?

Kanban (signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing.

It was developed by Toyota to improve manufacturing efficiency.

The system takes its name from the cards that track production within a factory.

Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement.

Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps.

One of the main benefits of kanban is to establish an upper limit to work in process inventory to avoid overcapacity.

A kanban system quickly responds to observed demand, in that it is used as a demand signal that immediately travels through the supply chain.

This ensures that intermediate stock held in the supply chain are better managed, and are usually smaller.

Where the supply response is not quick enough to meet actual demand fluctuations, a stock building may be deemed more appropriate and is achieved by placing more kanban in the system.

The kanban card is, in effect, a message that signals a depletion of product, parts, or inventory.

When received, the kanban triggers replenishment of that product, part, or inventory.

Consumption, therefore, drives demand for more production, and the kanban card signals demand for more product—so kanban cards help create a demand-driven system.

Electronic Kanban or E-Kanban differs from traditional kanban in using technology to replace traditional elements like kanban cards with barcodes and electronic messages.

E-kanban systems can be integrated into ERP systems, enabling real-time demand signaling across the supply chain and improved visibility.

So you wish to find out more about what is kanban in lean manufacturing, I did too and here's the outcome.

What is kanban in lean manufacturing interested me so I did some research study and published this to YT .

If you want to learn more about what is kanban system I advise you to take a look at our various other videos :

_________________________

Have I answered all of your concerns about what is kanban in lean manufacturing?

People who searched for what is kanban system likewise searched for lean manufacturing video.

Let us know in the comments if you have any question about E-Kanban or Kanban in ERP and we will be happy to answer.

Do let us know if there is any ERP related topic that you would like us to cover in a video and don't forget to subscribe to our channel, like and share this video^^

0:02:31

0:02:31

0:02:30

0:02:30

0:02:05

0:02:05

0:03:48

0:03:48

0:06:04

0:06:04

0:04:55

0:04:55

0:05:08

0:05:08

0:07:05

0:07:05

0:03:58

0:03:58

0:02:01

0:02:01

0:04:23

0:04:23

0:02:16

0:02:16

0:05:32

0:05:32

0:02:27

0:02:27

0:07:12

0:07:12

0:02:11

0:02:11

0:09:59

0:09:59

0:05:22

0:05:22

0:00:46

0:00:46

0:06:14

0:06:14

0:10:19

0:10:19

0:57:02

0:57:02

0:01:25

0:01:25

0:01:09

0:01:09