filmov

tv

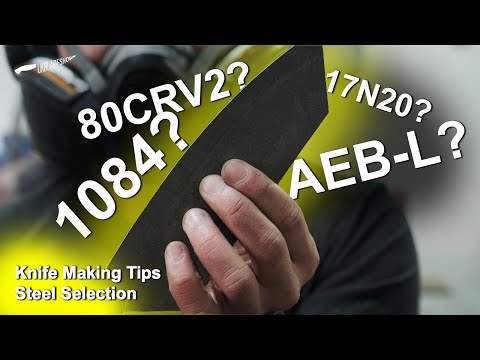

How to Heat Treat 80CrV2 Knife Steel

Показать описание

I found no less than 4 different recommendations for how to heat treat 80CrV2, and nobody seems to know whose advice to follow. I compare the heat treatments, test the resulting properties, and give my recommendation on how to heat treat it for different situations including with a forge vs a furnace, and for stock removal makers vs forging bladesmiths. And I compare the properties of 80CrV2 to other steels and explain how it is different than the slightly simpler 1080 steel.

Chapters:

00:00 Intro

00:31 80CrV2 Composition

03:43 Book plug

04:01 Heat Treating Steps

05:36 Normalizing

06:51 Grain refinement

07:18 Annealing

09:24 Please subscribe

09:55 New Experiments - Annealed Microstructure

11:58 Austenitizing and As-Quenched Hardness

14:50 Toughness Testing

16:12 Heat Treated Microstructure

17:21 Quench Oil and Hardenability

20:23 Tempering - Hardness and Toughness

21:19 Summarized Heat Treatment Steps

24:21 Thank You

Chapters:

00:00 Intro

00:31 80CrV2 Composition

03:43 Book plug

04:01 Heat Treating Steps

05:36 Normalizing

06:51 Grain refinement

07:18 Annealing

09:24 Please subscribe

09:55 New Experiments - Annealed Microstructure

11:58 Austenitizing and As-Quenched Hardness

14:50 Toughness Testing

16:12 Heat Treated Microstructure

17:21 Quench Oil and Hardenability

20:23 Tempering - Hardness and Toughness

21:19 Summarized Heat Treatment Steps

24:21 Thank You

How to Heat Treat 80CrV2 Knife Steel

Heat Treating An 80CRV2 Chopper | Knife Making | Vlog

How To Heat Treat A Knife | The 4 Steps You NEED To Know

Heat Treating and Tapering The Tang On The 80CRV2 Camp Knives | Knife Makers Vlog

3.5' Hunting Knife: Heat Treating for 80CRV2 Steel

Heat Treating A Forged 80crv2 Give Away Knife | Knife Making | Vlog

What Is 80CrV2 Used For?

NO MORE WARPS!!!!! heat treating tips!!!

Blade Heat Treat discussion with Jason Knight

Heat treating a pair of chef knives forged from 80CrV2 steel #knifemaking #bladesmith

Making a set of 3 kitchen knives from 80CrV2 steel FULL KNIFE BUILD Forging, Heat Treat, Sharpening

Heat-treating a 80CrV2 sword | ORCRIST

This 80CRV2 carbon steel knife warped during heat treat but we fixed it!

Using the Evenheat Kiln, Normalizing and Heat Treating 80CRV2 Steel

Heat treat quenching an 80crv2 blade.

EASY way to avoid bends in your knife (even BEGINNERS can do)!

How I Heat Treat My Knives In A Forge

DON’T BUY THIS if you're a hobbyist knife maker!

80crv2 steel penny test heat treat is spot on custom knife

how sharp an 80crv2 get?

Why 98% of knife makers pick the wrong steel according to a metallurgist

80crV2 steel hunter in the works, ready for heat treat!

I normalise my knife 3 times and I was WRONG!

80CRV2 Steel Review

Комментарии

0:24:52

0:24:52

0:07:40

0:07:40

0:12:13

0:12:13

0:09:42

0:09:42

0:21:52

0:21:52

0:13:10

0:13:10

0:12:37

0:12:37

0:05:34

0:05:34

0:07:03

0:07:03

0:00:44

0:00:44

0:17:59

0:17:59

0:00:29

0:00:29

0:12:37

0:12:37

0:04:41

0:04:41

0:03:28

0:03:28

0:04:46

0:04:46

0:10:20

0:10:20

0:07:21

0:07:21

0:00:32

0:00:32

0:00:35

0:00:35

0:11:07

0:11:07

0:00:14

0:00:14

0:09:58

0:09:58

0:01:46

0:01:46