filmov

tv

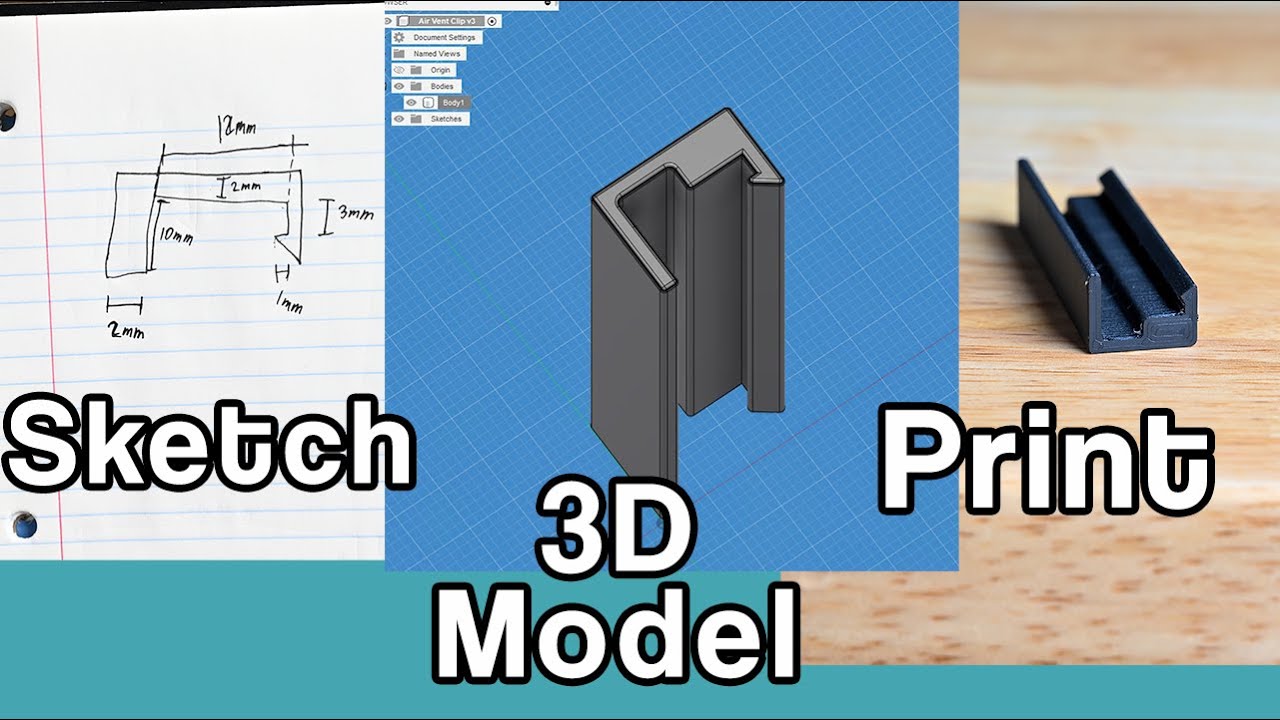

Designing Your First Functional 3D Printed Parts | Basic Fusion 360 3D Printing

Показать описание

It is time to take your 3D printing to the next level and create your own designs. The steps are simple, and the process is easier than you are expecting. I am using the free version of Fusion 360 for modeling.

There are 4 basic steps of creating your own prints.

First you need to think of what you want to make. This may sound basic, but it is a very important step. I am starting with some functional designs that will help around the house. I wouldn't start too advanced for your first design. That way you won't get discouraged.

Second it sketching and measuring. Digital Calipers are cheap and make this step really easy. Also, don't over think your sketch. These don't have to be pretty, just so you can understand what you wanted to create.

Third is 3d modeling of your sketches. I am using Fusion 360, because it is really powerful and makes basic designs easily once you get a hang of it. I would recommend skipping TinkerCAD because even a design as simple as this would have been so much harder in TinkerCAD, but took 5 minutes in Fusion 360.

The Fourth Step is printing, and I would recommend printing at a prototype quality. That means weaker and faster than you normally would, because your first design might not work.

The gear I use:

There are 4 basic steps of creating your own prints.

First you need to think of what you want to make. This may sound basic, but it is a very important step. I am starting with some functional designs that will help around the house. I wouldn't start too advanced for your first design. That way you won't get discouraged.

Second it sketching and measuring. Digital Calipers are cheap and make this step really easy. Also, don't over think your sketch. These don't have to be pretty, just so you can understand what you wanted to create.

Third is 3d modeling of your sketches. I am using Fusion 360, because it is really powerful and makes basic designs easily once you get a hang of it. I would recommend skipping TinkerCAD because even a design as simple as this would have been so much harder in TinkerCAD, but took 5 minutes in Fusion 360.

The Fourth Step is printing, and I would recommend printing at a prototype quality. That means weaker and faster than you normally would, because your first design might not work.

The gear I use:

Комментарии

0:18:28

0:18:28

0:10:37

0:10:37

0:18:52

0:18:52

0:04:35

0:04:35

0:19:18

0:19:18

0:05:03

0:05:03

0:06:38

0:06:38

0:09:49

0:09:49

0:15:38

0:15:38

0:22:03

0:22:03

0:15:11

0:15:11

0:24:02

0:24:02

0:10:14

0:10:14

0:24:27

0:24:27

0:11:36

0:11:36

0:11:36

0:11:36

0:28:23

0:28:23

0:13:33

0:13:33

0:01:00

0:01:00

0:12:56

0:12:56

0:01:01

0:01:01

0:10:25

0:10:25

0:30:49

0:30:49

0:10:38

0:10:38