filmov

tv

That's why i don't replace chipset/cpu/gpu :((((((((((((((((((((

Показать описание

Cheerleader girl bullies girl on team, teacher doesn't believe it #movie #shorts #video

Toilet Fill Valve Not Shutting Off / Don’t Replace / Fix Fast Cheap & Easy For Beginners

CEILING FAN PULL CHAIN SWITCH REPLACEMENT - How to replace a Pull Chain Switch on Ceiling Fan. Easy!

How to Fix a Leaky Outdoor Faucet - DON'T Replace It - Cheap & Easy

Don't Replace Your Toilet! Replace The Toilet Tank Parts!

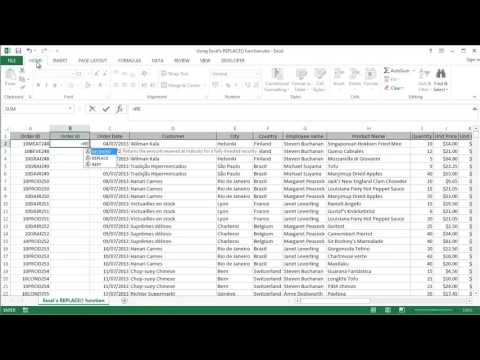

Microsoft Excel 2016 - Using the REPLACE() Function

How To REPLACE A Missing Tooth (Best Tooth Replacement Options)

Replace SPRINKLER HEAD in 5 Minutes - Rainbird - Hunter - Orbit

How to Replace Rear Wheel Bearings 2004-2009 Audi A4 Quattro

How to Diagnose and Replace a Starter

5 Signs It's Time To Replace Your Spark Plugs

Fix Leaking Shower Head or Bathtub Faucet | Rebuild & Replace Shower Valve

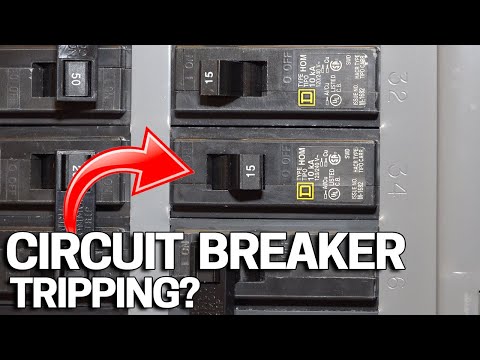

How To Replace or Change a Circuit Breaker in your Electrical Panel & Why it's Tripping

Corporate Logic 101 🤯 Coworker Quits | Work Life Animation Meme | Original Audio: Greg Langstaff

Replace A Toilet: Complete Step-by-Step Guide

How to Replace a Toilet Fill Valve || Installing the Fluidmaster Fill Valve and Flapper Kit

How to Replace a Transmission (Full DIY Guide)

When To Replace Struts - Monroe Shocks And Struts

How to replace an outside spigot / garden faucet

How to Replace a Window Regulator Motor (DIY)

How to Fix or Replace a Toilet Handle (Flush Lever) in 1 minute

How to replace your STIHL trimmer head AND how to fix it if it is STUCK!

Why It's Important To Check or Replace Your Engine Air Filter

How to Test and Replace a Bad Car Battery (COMPLETE Ultimate Guide)

Комментарии

0:01:00

0:01:00

0:04:47

0:04:47

0:03:18

0:03:18

0:07:35

0:07:35

0:10:39

0:10:39

0:03:43

0:03:43

0:04:18

0:04:18

0:04:51

0:04:51

0:29:37

0:29:37

0:13:11

0:13:11

0:02:23

0:02:23

0:17:34

0:17:34

0:06:11

0:06:11

0:00:57

0:00:57

0:23:00

0:23:00

0:04:33

0:04:33

0:28:24

0:28:24

0:04:00

0:04:00

0:03:14

0:03:14

0:18:59

0:18:59

0:03:49

0:03:49

0:08:04

0:08:04

0:01:56

0:01:56

0:28:50

0:28:50