filmov

tv

Re-assembling Ship's Generator Engine | Pt 3 | Chief MAKOi

Показать описание

Over the past few days, we have managed to dismantle, inspect, measure and recondition the various parts of the generator engine.

However, something unexpected happened...

Chief MAKOi

Seaman Vlog

However, something unexpected happened...

Chief MAKOi

Seaman Vlog

Re-assembling Ship's Generator Engine | Pt 3 | Chief MAKOi

Overhauling Our Ship's Generator Engine part 1| Seaman Vlog

Ship's Generator Engine Overhaul Pt. 2 : Cylinder Liner | Chief MAKOi Seaman Vlog

Ship🚢 Generator Repair #shorts#ship#engine

Huge Piston Overhaul on Ship's Main Engine | Chief MAKOi Seaman Vlog

Ship's Engine Maintenance : Fuel Injectors | Chief MAKOi

Their Boat Engine Fell Off

ABB shaft generators - Designed for easy installation on board

MAN B&W Generator Turbocharger Overhaul #dieselengine #turbocharger #marineengineer

Small Boat Powered by Mercury 300R: Smooth and Powerful Performance

Fuel Oil Purifier Overhaul | Selfjector | Chief MAKOi

Jet engine startup! Viper 11 MK22 Turbojet.

Just wait until you hear these twin V16s fire up🔥🤯#racingboat #engine #rawpower

Titanic - Full Size Replica Being Built In China🙏

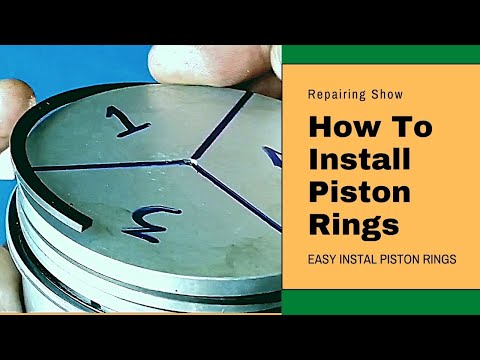

Piston Rings Installation Easily l How To Install Piston Rings

Old Generator 15000w Restoration Videos

Amazing Diesel Generator Walk Around & Ship Engine Room Tour

ABB Azipod® propulsion unit assembly Timelapse

J-35A fighter jet turbojet engine model

This Engine Is So Big Richard Hammond Can Walk Inside It | Richard Hammond's Big

ELECTRICITY ON SHIP'S ||SHIP AUXILIARY ENGINE ||DIESEL GENERATOR |MAN B&W ENGINES#engine #s...

Do you want to better your life? #philippines #angelescity #expat #pampanga #travelvlog

Turbocharger maintenance process

Engine block transformation after chemical dipping

Комментарии

0:13:24

0:13:24

0:14:07

0:14:07

0:15:21

0:15:21

0:00:15

0:00:15

0:20:56

0:20:56

0:12:41

0:12:41

0:00:13

0:00:13

0:03:09

0:03:09

0:11:34

0:11:34

0:00:13

0:00:13

0:17:26

0:17:26

0:00:24

0:00:24

0:00:19

0:00:19

0:00:16

0:00:16

0:03:12

0:03:12

0:32:18

0:32:18

0:10:14

0:10:14

0:03:17

0:03:17

0:00:15

0:00:15

0:07:38

0:07:38

0:04:37

0:04:37

0:00:16

0:00:16

0:00:13

0:00:13

0:00:12

0:00:12