filmov

tv

Print Reading and Tolerancing in the Machine Shop

Показать описание

Here is my brief, and hopefully thorough enough, introduction to reading prints and understanding tolerances.

Check out my new Patreon page!

Check out my new Patreon page!

Print Reading and Tolerancing in the Machine Shop

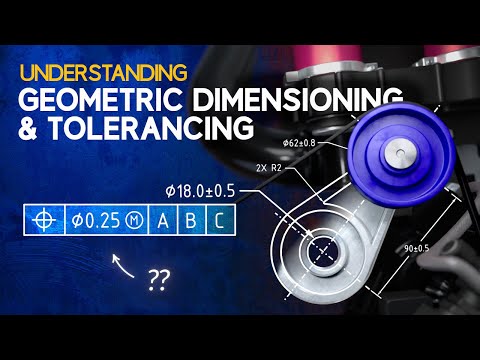

Understanding GD&T

Reading GD&T Drawings Step by Step

Engineering Tolerances Explained

Examples of Determining the Tolerance on an Engineering Drawing? || ED Fundamentals Course Preview

Print Reading: Applying Dimensions

The Basics of Reading Engineering Drawings

Understanding Engineering Drawings

Print Reading Part 1

Print Reading: Lines & Lettering

Print Reading: Introduction

Print Reading Quiz

What is GD&T in 10 Minutes

How to Apply GD&T Position Tolerance to a Hole

How to Read engineering drawings and symbols tutorial - part design

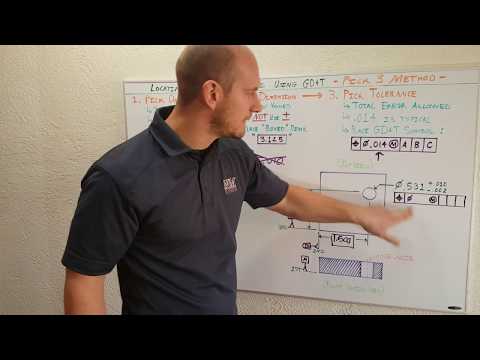

#GD&T (Part 1: Basic Set-up Procedure)

Identifying Tolerances

GD&T example: 2 parts with datums, position, and profile tolerance

Blueprint Reading 101| The Basics You Need to Know

CNC machinist made easy: blueprint reading video#6

Reading Decimals in the Shop

GD&T ASME Y14.5: Detail Drawings DO NOT Apply at the Assembly Level, Fundamental Rule 'P&ap...

Engineering Drawing Tolerances: 15 Minute Introduction

Job Planning, Benchwork, & Layout - Print Reading: Basic Tolerancing

Комментарии

0:22:10

0:22:10

0:29:32

0:29:32

0:08:25

0:08:25

0:02:31

0:02:31

0:02:01

0:02:01

0:09:04

0:09:04

0:23:58

0:23:58

0:22:34

0:22:34

0:16:15

0:16:15

0:23:57

0:23:57

0:10:30

0:10:30

0:40:27

0:40:27

0:10:09

0:10:09

0:03:16

0:03:16

0:04:43

0:04:43

0:15:53

0:15:53

0:04:27

0:04:27

0:05:07

0:05:07

0:10:30

0:10:30

0:21:31

0:21:31

0:03:56

0:03:56

0:05:42

0:05:42

0:15:38

0:15:38

0:06:19

0:06:19