filmov

tv

WELL DRILLING 101 | Every Step Explained

Показать описание

A fulll breakdown of the entire well drilling process from start to finish.

NOAH Tiny House Certification:

Tell 'em Dan Richfield sent ya!

STRYKER TRAILERS:

256-310-1902

Ask for Chuck Graham!

We will be publishing plans for this house later this year at:

OFFGRIDBUILD.COM

NOAH Tiny House Certification:

Tell 'em Dan Richfield sent ya!

STRYKER TRAILERS:

256-310-1902

Ask for Chuck Graham!

We will be publishing plans for this house later this year at:

OFFGRIDBUILD.COM

WELL DRILLING 101 | Every Step Explained

How a Deep Water Well is Drilled - Drilling 101

Water Well Drilling 101

Drilling Animation

The process of digging Wells with shovels

Rotary drilling equipment- Good tools and machinery make work easy

Water well drilling 101: What happens when a large vein of water is hit

How Wells & Aquifers Actually Work

Translation Rights 101 - a Free for all IBPA webinar

Well Drilling 101 Skinner Well Drilling

Watch a Water Well Being Drilled

Drilling 101 How a deep water well is drilled

Well Drilling 101- How Is A Well Drilled? You Better Be Able To Lay Pipe!

Borewell Drilling 101, all day everyday🌊🎯🌊 another day at the office. #shorts #borewell #waterwell...

Drilling a Water Well from Start to Finish

Drilling 101 - Why We Drill a Well? #oilgas #drilling #learningbite

Crawler type ground water drilling rig machine

Drilling 101

Patriot Energy Rig Site Drilling Process

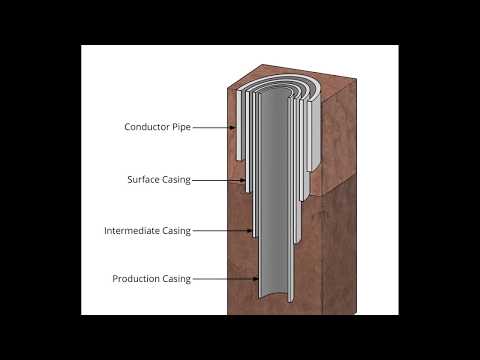

CasingStrings

Horizontal Directional Drilling / Boring (HDD): How the Drill Bit is Steered

Oil and Gas 101: Offshore Drilling at Woodside

Water Well Drilling Outer Protective Casing (Explained)

The process of drilling a deep well under a pipe- Good tools and machinery make work easy

Комментарии

0:17:08

0:17:08

0:05:32

0:05:32

0:13:10

0:13:10

0:05:59

0:05:59

0:00:13

0:00:13

0:00:14

0:00:14

0:00:16

0:00:16

0:14:13

0:14:13

1:10:13

1:10:13

0:02:07

0:02:07

0:08:20

0:08:20

0:05:32

0:05:32

0:08:01

0:08:01

0:00:11

0:00:11

0:12:34

0:12:34

0:10:56

0:10:56

0:00:16

0:00:16

0:08:57

0:08:57

0:07:15

0:07:15

0:00:26

0:00:26

0:02:08

0:02:08

0:05:35

0:05:35

0:03:11

0:03:11

0:00:25

0:00:25