filmov

tv

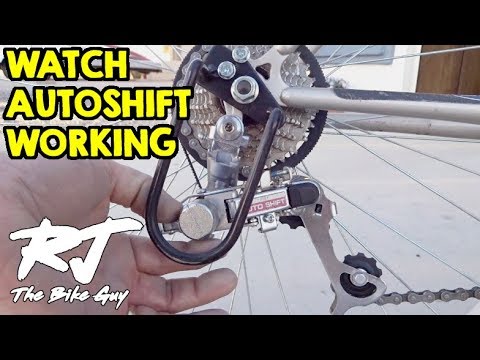

15 speed Cambiogear Bicycle Transmission

Показать описание

15 speeds on front chainring (at the crank) made of Dupont Zytel (nylon strengthened with chopped fiberglass). Invented and designed by prolific engineer Royce Husted near Chicago for the Excel corporation. 6 segments expand and contract to produce 15 sizes of hexagonal chainring between two plates. Only 2 of the segments have teeth; the other 4 are just place holders. The fixed outer plate has radial grooves to lock the segments into place. The inside plate has 6 spirals (which act as inclined planes) with distinct indents for exact gear position. This plate can be stopped temporarily with a brake that acts on its outer edge. You pedal normally to upshift and backpedal to downshift. A complete (or partial) downshift to any gear only takes a second or less. Mr. Husted also designed the world's best bicycle brake (not shown in this video) consisting of an additional groove external to the main rim in which a loop of Kevlar string loosely rides. The "cambio" in Cambiogear means "change" in Spanish. There was another 50 speed transmission called the Biocam and these two devices are not related. The Biocam was a cam-following kidney bean shaped chainring which drove both sides of the rear wheel with dual chains. Its advantage was the ability to easily pedal a 150 inch gear due to power curve modification. You could pedal effortlessly VERY slowly in extremely high gear.

Комментарии

0:04:54

0:04:54

0:06:58

0:06:58

0:01:50

0:01:50

0:00:10

0:00:10

0:03:21

0:03:21

0:00:23

0:00:23

0:05:51

0:05:51

0:00:21

0:00:21

0:01:09

0:01:09

0:03:47

0:03:47

0:00:16

0:00:16

0:00:15

0:00:15

0:03:07

0:03:07

0:02:04

0:02:04

0:02:18

0:02:18

0:00:19

0:00:19

0:01:34

0:01:34

0:00:11

0:00:11

0:01:57

0:01:57

0:01:31

0:01:31

0:00:10

0:00:10

0:01:59

0:01:59

0:00:17

0:00:17

0:00:21

0:00:21