filmov

tv

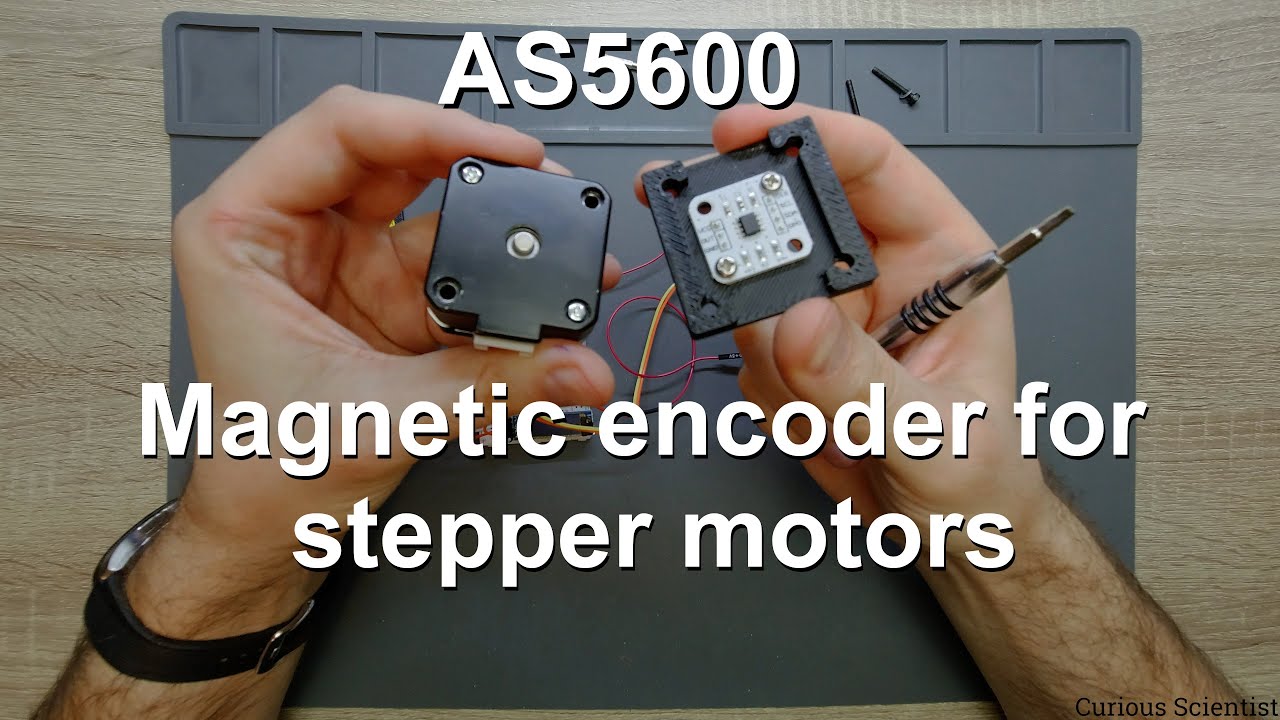

AS5600 magnetic position encoder - best encoder for stepper motors

Показать описание

In this video I show you how to use the AS5600 magnetic position encoder. This is a very powerful chip for projects where you need a precise information about the position of a shaft. Therefore, it is extremely useful for stepper motor-related projects because you can use the sensor to directly measure the displacement of the shaft of the stepper motor. Its angular resolution is 0.08789°/bit, so if you use it with a stepper motor that has a 1.8° angular resolution, you can use the motor up to 3200 step/turn microstepping and still get decent numbers.

Please don't forget to subscribe if you like the content!

If you want to support my work, please consider buying the parts using my affiliate links:

Please don't forget to subscribe if you like the content!

If you want to support my work, please consider buying the parts using my affiliate links:

AS5600 magnetic position encoder - best encoder for stepper motors

This Component solves 'All' Motor Problems?! (Motor Encoder) EB#58

N20 miniature DC geared motor with AS5600 encoder and PID

AS5600 Position Sensors IoT Demo Kit

AS5048A 14-bit magnetic position encoder

Custom AS5600 PCB for NEMA17-type stepper motors

Cheap 3D Printed Absolute Encoder Knob #Shorts

Magnetic rotary encoder vs stepper motor accuracy

Measuring speed and position using the AS5600 magnetic encoder

ams OSRAM AS5172E High-Resolution Magnetic Position Sensor | New Product Brief

How to program the AS5600

AS5600 magnetic encoder test on my own designed 2 stage planetary gearbox robot arm actuator

Inexpensive Robot Feedback on stepper motors with AS5600 Magnetic Encoder

AS5600 et TCA9548

A great cheap encoder -- the AS5600

How to programs encoder AS5600

Overengineered 'potentiometer' using the AS5600 magnetic encoder

step motor with as5600 encoder testing

AS5600 Magnetic encoder - A practical example

DIY magnetic encoder

AS5600 Robot Position Encoder 12Bit Testing with Arduino source

AS5600 Magnetic Rotary Encoder with analog output

Open-Source Inverted Pendulum | Grove - 12-bit Magnetic Rotary Position Sensor / Encoder (AS5600)

AS5600 Magnetic Encoder Installation & Coding

Комментарии

0:48:18

0:48:18

0:11:34

0:11:34

0:44:26

0:44:26

0:01:42

0:01:42

0:36:21

0:36:21

0:20:00

0:20:00

0:00:53

0:00:53

0:05:41

0:05:41

0:38:22

0:38:22

0:01:13

0:01:13

0:04:11

0:04:11

0:00:17

0:00:17

0:03:01

0:03:01

0:00:22

0:00:22

0:03:27

0:03:27

0:05:57

0:05:57

0:17:24

0:17:24

0:01:08

0:01:08

0:44:38

0:44:38

0:00:24

0:00:24

0:01:23

0:01:23

0:07:29

0:07:29

0:01:30

0:01:30

0:06:08

0:06:08