filmov

tv

Clever Mechanism for DIY Mobile Tool Base

Показать описание

I got some cheap 2" casters, some scrap wood and a half inch threaded rod to create this DIY mobile tool base that keeps the wheels retracted when you want the tool to stay still and down when you want to move it in any direction.

Join this channel:

Support DIY Builds on Patreon:

Buy a T-shirt to support the channel:

Visit my website for free plans and see viewer builds:

Follow me on Instagram:

Follow me on Facebook:

#DIY

#Woodworking

#Carpentry

Join this channel:

Support DIY Builds on Patreon:

Buy a T-shirt to support the channel:

Visit my website for free plans and see viewer builds:

Follow me on Instagram:

Follow me on Facebook:

#DIY

#Woodworking

#Carpentry

Clever Mechanism for DIY Mobile Tool Base

Wooden Lock & Secret Key. Simple DIY #woodworking #woodcraft #diy #woodwork

Hidden Folding Dining Table Design Idea

Five MUST SEE ways to make your workshop mobile!

Foldable Table 90 Degree Lock Hinge Design

PVC Pipe Hacks You'll Wish You Knew Sooner #shorts #diy #skills #satisfying

DIY Retractable Casters Wheels - A Simple And Effective Solution!

Hidden Drawer with Magnetic Latch Concept

Top 8 Ingenious Mechanical Mechanisms You Should Know! | Engineering Marvels

How Chainsaw Kickback Works 😬

More screens, more productivity! This portable monitor setup weighs only 1.1kg (2.4lbs)

Wood Saw Machine Tool #Gadget #Gadgets 😉SUBSCRIBE PLEASE!👇👇👇 #shorts

Wirtz pumps are really clever

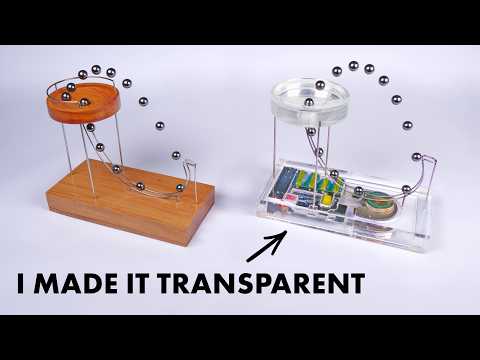

You can't hide the batteries when it's transparent!

3D printed Tilt Phone Stand - Ratchet Edition

portable ramp

Secret Storage Solutions

Unlock Your Car with a Battery and Magnet? This Clever Hack Will Blow Your Mind

Cable telescopic Mast Working Animation #3dcad #cable #telescopic #mechanical #engineering #protools

Smart Dustbin DIY #smartgadgets #smartdustbin #smarthouse #electrocse

Smart Secret Storages and Space Saving Furniture Innovations

Very resourceful GIRL 🤯 #camping #survival #bushcraft #outdoors

Wireless charger hack

Flywheel Free Energy?! #technology #fake #funny

Комментарии

0:08:45

0:08:45

0:00:13

0:00:13

0:00:05

0:00:05

0:08:18

0:08:18

0:00:05

0:00:05

0:00:25

0:00:25

0:07:10

0:07:10

0:00:16

0:00:16

0:08:05

0:08:05

0:00:24

0:00:24

0:00:28

0:00:28

0:00:19

0:00:19

0:12:05

0:12:05

0:09:26

0:09:26

0:00:17

0:00:17

0:00:29

0:00:29

0:00:15

0:00:15

0:00:30

0:00:30

0:00:07

0:00:07

0:00:12

0:00:12

0:10:37

0:10:37

0:00:24

0:00:24

0:00:30

0:00:30

0:00:39

0:00:39