filmov

tv

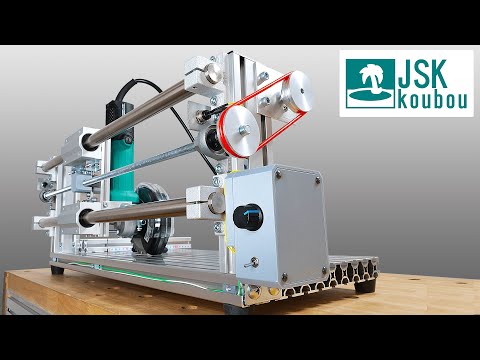

Amazing device to cut metal with high precision

Показать описание

I made a semi-automatic grinder cutter.

When the switch is turned on, the motor rotates to move the grinder, and when the disconnection is completed, the movement stops.

For safety, the grinder body is turned on and off manually.

In addition, since the grinder body can be easily attached and detached, it can be used as it is as a hand tool.

Amazing device to cut metal with high precision

Nibblers vs Single Cut Shears vs Double Cut Shears - Cutting Sheet Metal - Right Tool For the Job

Top 10 Ways to Cut Metal WITHOUT an Angle Grinder - A Comprehensive Beginners Guide

INSANE Tapered Cut on Wire EDM #shorts

Amazing cube and sphere made by wire cut EDM machine

How To Make The Magical Multitool Cut!

Best Metal Cutting Blade? “Dry Cut” vs “Abrasive” vs “Diamond' Blade. Diablo, DeWalt, Makita...

Surprisingly Fascinating Machine

10 Tools for Cutting Metal: How to Cut Metal for Welding Projects

$9 harbor freight drill master dremel tool. Will it cut exhaust pipe?

How do you cut steel? SAFER - STRONGER - OK Diamond Metal Plus Cutting Wheel

how to cut a tubular steel by grinder cutter #shortvideo

Terrified of Angle Grinders? How to Cut Steel Fast & Cheap WITHOUT Losing Any Fingers!

How to cut a thread on a manual lathe (Intermediate method ideal for home workshop & hobby engin...

13 Ways to Cut Metal

G-Code Cuts Better Chips

Did you know you can cut metal with a circular saw!?! 🍊 #woodandmetal #tools #corrugatedsteel

TOLSEN Straight Cut Tin Snips for Cutting Metal Sheet Heavy Duty Metal Cutter

Broken Tool Makes Unbelievable Deep Cut

Ultimate Cutting Power! ⚡ Precision Saw for Wood & Metal

Perfect Cut With a Torch on 1” plate

Milwaukee m12 cut off tool

One #TOOL to Replace ALL Others! Cut Metal with EASE

Big Cutting in Small Tool! Easily Cut Metal w/ Mini Rotary Metal Shear - Eastwood

Комментарии

0:23:56

0:23:56

0:02:41

0:02:41

0:12:19

0:12:19

0:00:37

0:00:37

0:01:16

0:01:16

0:00:35

0:00:35

0:17:56

0:17:56

0:00:35

0:00:35

0:18:34

0:18:34

0:00:33

0:00:33

0:25:31

0:25:31

0:00:48

0:00:48

0:02:23

0:02:23

0:12:07

0:12:07

0:20:01

0:20:01

0:00:32

0:00:32

0:00:23

0:00:23

0:01:15

0:01:15

0:00:41

0:00:41

0:00:14

0:00:14

0:00:59

0:00:59

0:00:31

0:00:31

0:00:28

0:00:28

0:01:03

0:01:03