filmov

tv

How Crankshaft Casting Process Are Done || Complete Casting Process of Crankshafts Inside Foundry

Показать описание

Cast Cranks are created by pouring molten material (typically cast iron) into a mold to create a raw casting. The benefits of this process casting include lower cost, inexpensive tooling, and minimal machining required to produce a finished product

#crankshaftcastingprocess #sandcastingcrankshaft #ironcrankshaftcadting

#crankshaftcastingprocess #sandcastingcrankshaft #ironcrankshaftcadting

How Crankshaft Casting Process Are Done || Complete Casting Process of Crankshafts Inside Foundry

Modern Production of Crankshafts for Engines

Manufacturing of Truck CrankShafts // The Most Amazing Production & Machining Complete Process

How is a Crankshaft Machined After Casting? Step by Step Walkthrough in Factory

EVERYTHING about the CRANKSHAFT - Function | Manufacturing | Different types | Forged | Billet

NovaCast - Crankshaft Casting Simulation

Casting a Racecar Cylinder Head - Complete Process

How To Crankshaft Casting All Process || Making of Crankshaft In local factory ||

BMW Engine Block Casting | HOW IT'S MADE

Making of a Crankshaft Through Casting Method

Production of Crankshafts in Factory Complete Process || Machining 6 Cylinder Engine Crankshaft

Manufacturing Process of Crankshaft with Amazing Skills

Amazing manufacturing of car engine parts. Crankshaft.

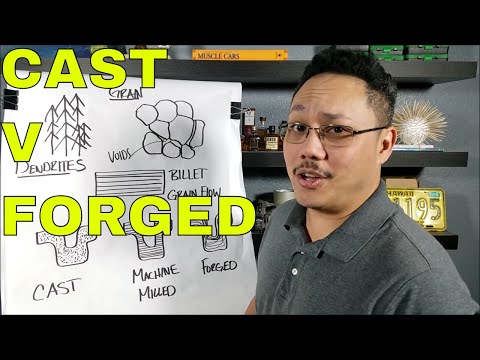

Forged vs Cast

How Engines Are Made

Production of Crankshafts in Factory Complete Process || Machining 3 Cylinder Engine Crankshaft

Sandcasting of a V8 crankshaft | FLOW-3D CAST

Forged vs Cast Piston Strength!

Forged Crankshaft Manufacturing Process

Dangerous Biggest Crankshaft Forging Process in Metal Heavyweight Forging Factory Germany, US, China

CAST VS FORGED PARTS WHY CAST IS BAD AND WHY FORGED IS BETTER

How To Tell The Difference Between A Cast And Forged Crankshaft… The Easy Way! #shorts

How Expert Machinist Make 5 Cylinder Ammonia Compressor Crankshaft- Compressor Crankshaft |

Pouring On the Quality | Making a Caterpillar Engine Block at the Mapleton, IL Foundry

Комментарии

0:15:13

0:15:13

0:10:15

0:10:15

0:36:35

0:36:35

0:46:04

0:46:04

0:27:48

0:27:48

0:00:26

0:00:26

0:03:44

0:03:44

0:40:14

0:40:14

0:11:22

0:11:22

0:18:38

0:18:38

0:37:36

0:37:36

0:01:00

0:01:00

0:03:13

0:03:13

0:00:39

0:00:39

0:07:34

0:07:34

0:41:37

0:41:37

0:00:16

0:00:16

0:00:44

0:00:44

0:06:05

0:06:05

0:10:28

0:10:28

0:04:16

0:04:16

0:00:59

0:00:59

0:52:37

0:52:37

0:03:03

0:03:03