filmov

tv

#9 ARM STM32 Microcontroller Tutorial - Solder SMD Chips Like a BOSS!!

Показать описание

Purchase my new book: Arm Microcontroller Programming and Circuit Building Volume 1

Learn how to solder a fine pitch chip.

Links to the software:

Parts you will need in your prototyping environment:

Kits to get you up to speed quickly:

If you already have the microcontroller, here are some breakout boards to use:

STM-Link V2 Programmer:

Prototyping Breadboards:

Resistor Assortment Kit:

Solid core hook-up wire 22 AWG:

LEDs and Displays:

Trimmer potentiometers:

The Dynamixel servo I will be using in the USART videos:

Microfarad Capacitor Assortment:

Electrolytic Capacitor Assortment:

Learn how to solder a fine pitch chip.

Links to the software:

Parts you will need in your prototyping environment:

Kits to get you up to speed quickly:

If you already have the microcontroller, here are some breakout boards to use:

STM-Link V2 Programmer:

Prototyping Breadboards:

Resistor Assortment Kit:

Solid core hook-up wire 22 AWG:

LEDs and Displays:

Trimmer potentiometers:

The Dynamixel servo I will be using in the USART videos:

Microfarad Capacitor Assortment:

Electrolytic Capacitor Assortment:

#9 ARM STM32 Microcontroller Tutorial - Solder SMD Chips Like a BOSS!!

#5 ARM STM32 Microcontroller Tutorial - The 4 Basics to Control ALL!!

Amazing arduino project | Check description to get free money.

final year diploma engineering project #viral #mechanical

#2 ARM STM32 Microcontroller Tutorial - Setting Up the Prototyping Environment

Lecture 9: Interrupts

#8 ARM STM32 Microcontroller Tutorial - Change the Internal Clock Speed! (automated and manual)

#10 ARM STM32 Microcontroller Tutorial - USART Initialization Part 1

Easy & Powerful Arduino Alternative? STM32 Beginner's Guide

54. How to Make Push Button External Interrupts - ARM STM32 Microcontroller Tutorial

58. How to: I2C Circuit and Initialization - ARM STM32 Microcontroller Tutorial

STM32 Guide #2: Registers + HAL (Blink example)

#3 ARM STM32 Microcontroller Tutorial - Installing the IDE and Monitoring Software

1. How to Program and Develop with ARM Microcontrollers - A Tutorial Introduction

ARM architecture | Embedded Systems | Lec-9 | Bhanu Priya

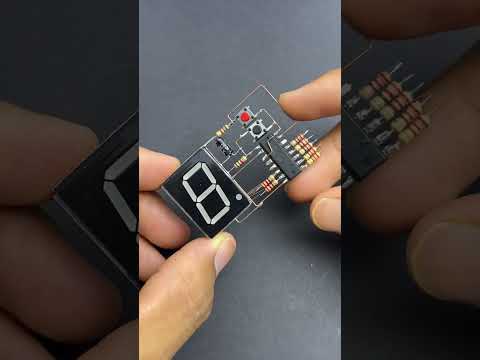

How to make a LED digital counter using 7- Segment Display

9. How to Resolve Can not connect to target for the STM32 and ST-Link

STM32 Project 9

STM32-F446RE microcontroller simple test

Arduino vs. Wires! And the winner is?

Day 01 - Introduction to Arm & STM32

Best Programming Languages #programming #coding #javascript

Robot Control with STM32 #embedded #robotics #stm32 #kinematics #linux #eclipse #programming #diy

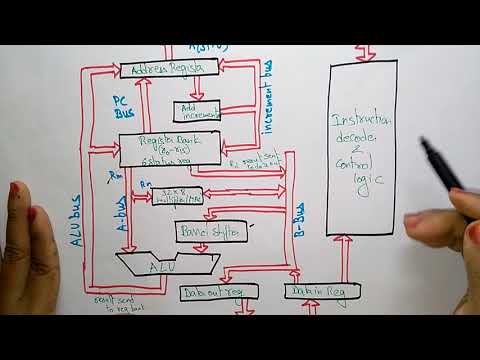

6. STM32 Microcontroller Architecture

Комментарии

0:24:32

0:24:32

0:28:21

0:28:21

0:00:16

0:00:16

0:00:43

0:00:43

0:11:38

0:11:38

0:20:43

0:20:43

0:45:11

0:45:11

0:32:22

0:32:22

0:09:49

0:09:49

0:19:36

0:19:36

0:17:08

0:17:08

0:30:02

0:30:02

0:24:50

0:24:50

0:04:16

0:04:16

0:16:29

0:16:29

0:01:00

0:01:00

0:03:14

0:03:14

0:00:08

0:00:08

0:00:08

0:00:08

0:00:59

0:00:59

0:56:38

0:56:38

0:00:16

0:00:16

0:00:16

0:00:16

0:06:09

0:06:09