filmov

tv

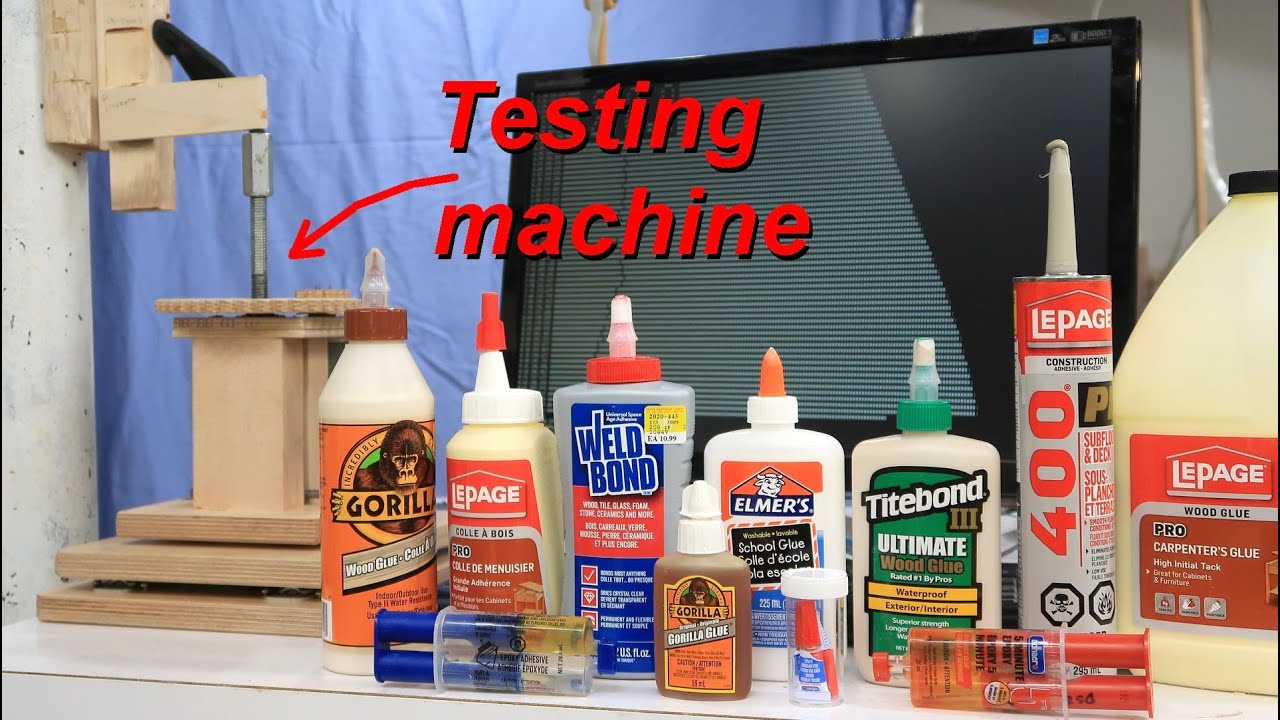

Which glue is strongest? Testing with my computerized tester.

Показать описание

Testing different types of woodworking glue on my glue strength testing apparatus.

First with construction lumber, then with maple hardwood.

First with construction lumber, then with maple hardwood.

Which glue is strongest? Testing with my computerized tester.

Wood Glue Strength Test - Titebond III vs Titebond Original vs Gorilla Glue

Gorilla VS Titebond - Ultimate Wood Glue Test

Testing Cheap Vs Expensive Super Glue!

Which CA Glue is the BEST... Let's Find Out!

Best And Strongest Jewelry Glue | Testing 4 Glues For Metal To Gemstones | Stones and Findings

Super Glue Metal Bonding - How Strong is Super Glue?

WORLD’S STRONGEST GLUE THEN THIS HAPPENED! #shorts

Gorilla Super Glue Review

Which Fabric Glue is the Best? In Depth Review 2024 (Testing Fabrics, Consistency, Strength)

Which Wood Glue is Best? Let's find out! Showdown with Titebond, Flex Glue, Elmer's &...

Testing construction adhesives as woodworking glue

what’s the strongest super glue #spaceexploration #modelrocket #superglue #glue

Which Super Glue Brand is the Best? Let's find out!

Testing the World's Strongest Nail Glue

Loctite Professional vs Original Super Glue

Testing the World's Strongest Nail Glue

The Best Glue For Cardboard (18 Glues Tested)

Best Glue For Wood To Metal (8 Glues Tested)

Super Glue Strength Test | Cotton Miracle vs Baking Soda

Is Glue Stronger Than Wood? No!

DON'T USE SUPER GLUE! Try This Instead..(Epoxy Adhesive/5-Minute Epoxy/Epoxy Glue)

I Tested The Cheapest Glue On Amazon!

How Strong is Wood Glue Actually? Shocking Results!

Комментарии

0:12:50

0:12:50

0:09:18

0:09:18

0:12:56

0:12:56

0:00:33

0:00:33

0:16:47

0:16:47

0:10:15

0:10:15

0:02:01

0:02:01

0:00:16

0:00:16

0:00:41

0:00:41

0:10:23

0:10:23

0:14:24

0:14:24

0:06:21

0:06:21

0:00:54

0:00:54

0:12:16

0:12:16

0:00:42

0:00:42

0:00:53

0:00:53

0:00:24

0:00:24

0:10:42

0:10:42

0:14:37

0:14:37

0:01:16

0:01:16

0:01:00

0:01:00

0:06:02

0:06:02

0:15:32

0:15:32

0:01:00

0:01:00