filmov

tv

Installing Windows Ep.80

Показать описание

Enjoy EC? Join Essential Craftsman Academy!

This is the best way to support Essential Craftsman and you get a LOT of perks as a bonus!

Did you know we have a podcast?

If you are going to hire a contractor for a big project PLEASE read our ebook first!

Amazon Affiliate Links:

Video Equipment and Misc.

Learn more about Essential Craftsman

Thank you, be safe, and be grateful.

This is the best way to support Essential Craftsman and you get a LOT of perks as a bonus!

Did you know we have a podcast?

If you are going to hire a contractor for a big project PLEASE read our ebook first!

Amazon Affiliate Links:

Video Equipment and Misc.

Learn more about Essential Craftsman

Thank you, be safe, and be grateful.

Installing Windows Ep.80

Putting in our Log Cabin Windows! Big Difference! / Ep80 / Outsider Log Cabin

Installing Windows 1.0 on an '80s Zenith Portable PC!

Windows 1.0 with Steve Ballmer (1986) (HQ, 60FPS)

Salt & Tar: Episode 80-Windows Finally!

All New Windows XP 20th Anniversary Build

Startup of an old 386 computer running windows 3.11

Windows XP 20th Anniversary All New PC Build

How to install SQL Server 2022 and SQL Server Management Studio SSMS - Episode 5 (Home Lab Series)

Your Mac Can Run Windows!

Building a Windows 95 PC! Socket 7 AMD K6 & 3Dfx

MUNBYN How to install pos-80 Windows driver

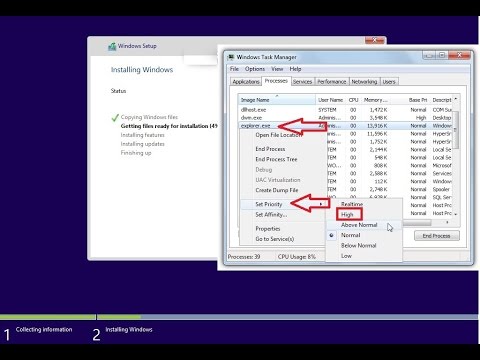

How to Fast & Speed Install Windows 10/8.1/7 OS (Easy)

How To Make Windows 11 look like Windows XP

Boot Windows 10 from an iPod Classic.

Windows 95 ASMR #retrocomputer

Millions of People Still Use Windows XP

Here’s why I like to trim windows/doors on brick homes. Brick molding FTW! #windows #construction

Installing Windows 95 From 29 Floppy Disks - An Attempt

Exterior Insulation - Windows are a PAIN

How to install 58 80mm Bluetooth printer on windows 10 system? With configuration user guide

Install Windows 98 from USB Flash Drive with Easy2Boot

Young People Try Windows 98

HOW TO INSTALL WINDOWS XP ON LAPTOP

Комментарии

0:14:59

0:14:59

0:20:52

0:20:52

0:22:04

0:22:04

0:01:07

0:01:07

0:17:27

0:17:27

0:13:38

0:13:38

0:01:06

0:01:06

1:03:18

1:03:18

0:28:54

0:28:54

0:04:22

0:04:22

0:47:06

0:47:06

0:00:14

0:00:14

0:02:09

0:02:09

0:21:29

0:21:29

0:13:13

0:13:13

0:00:30

0:00:30

0:05:20

0:05:20

0:01:01

0:01:01

0:30:12

0:30:12

0:12:46

0:12:46

0:02:21

0:02:21

0:12:59

0:12:59

0:21:18

0:21:18

0:12:09

0:12:09