filmov

tv

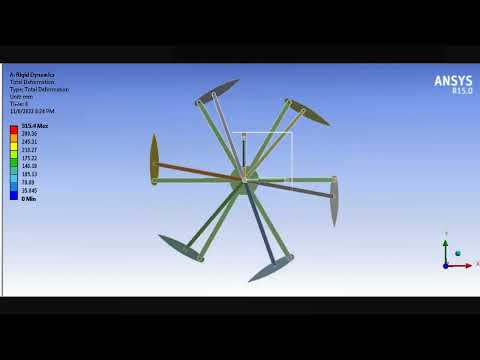

The Cyclorotor Is Now a Match For Propellers!

Показать описание

The cyclorotor now has a thrust to weight ratio of 4.69:1, which I believe means that it now has nearly double the thrust to weight ratio of any other cyclorotor. The max thrust produced (328g) and power consumed (78 Watts) are the exact same as a 6x3 conventional propeller (A 6x3 prop has only a 20% difference in the disk loading from the cyclorotor).

Sources:

University of Maryland cyclocopter - Elena Shrestha's youtube

Texas A&M cyclocopter - Mobile Benedict's youtube

Cyclotech cyclocopter - Cyclotech website and youtube

Specs:

- 150mm rotor diameter

- 150mm airfoil wingspan

- NACA 0022 airfoil with a 50mm chord

- 2004 1900kv motor

- 6:1 GT2 belt driven gear ratio

- ~3000 rpm at max throttle

- 328g static thrust

- 70g rotor weight

- 4.0 g/W

Sources:

University of Maryland cyclocopter - Elena Shrestha's youtube

Texas A&M cyclocopter - Mobile Benedict's youtube

Cyclotech cyclocopter - Cyclotech website and youtube

Specs:

- 150mm rotor diameter

- 150mm airfoil wingspan

- NACA 0022 airfoil with a 50mm chord

- 2004 1900kv motor

- 6:1 GT2 belt driven gear ratio

- ~3000 rpm at max throttle

- 328g static thrust

- 70g rotor weight

- 4.0 g/W

The Cyclorotor Is Now a Match For Propellers!

CycloRotor | Start Outdoor Flying

Cycloidal Rotor Drone: The Cyclocopter

Discover CycloTech #4 | What is the CycloRotor and why it´s a game changer for aviation

CycloRotor: Is this the future of eVTOL Electric Propulsion System?

The Engineering of ARF's Cyclocar VTOL

Quad Cyclocopter Demo

The Genius of Cycloidal Propellers: Future of Flight?

CycloRotor: Revolutionary eVTOL Propulsion System

Cycloidal Rotor Airplane: The Cycloplane

CycloRotor | Wind Tunnel Test, 2023

World’s First Flying Car with CycloRotors - CycloTech CruiseUp

Cycloidal Rotor - Pitch Control Mechanism (Voith Schneider propeller)

First Air Car with CycloRotors | Maximum Speed 150 Km/h | New CycloTech CruiseUp eVTOL

CycloTech First Flight

CycloRotor | Outdoor Noise Test 2022

Cyclorotor testing

CycloRotors | Enable 360° Thrust Vectoring

Futuristic eVTOL Propulsion System | Cyclorotor / Cyclogyro | Air Car

Cyclotech CycloRotor #flyingcar #evtol #futuretech #dji #dronevideo #flying

CycloRotor Is this the future of eVTOL Electric Propulsion System

Cyclorotor : Why This Could Be Future Of eVTOL Electric Propulsion System !!

Cyclocopter Oscillations While PID Tuning

Discover CycloTech #3 | About CycloRotor Technology

Комментарии

0:02:37

0:02:37

0:02:46

0:02:46

0:06:55

0:06:55

0:02:33

0:02:33

0:06:06

0:06:06

0:07:49

0:07:49

0:01:02

0:01:02

0:11:36

0:11:36

0:02:46

0:02:46

0:09:05

0:09:05

0:02:05

0:02:05

0:02:36

0:02:36

0:00:21

0:00:21

0:02:39

0:02:39

0:01:37

0:01:37

0:03:38

0:03:38

0:01:06

0:01:06

0:00:56

0:00:56

0:12:02

0:12:02

0:00:25

0:00:25

0:04:17

0:04:17

0:08:03

0:08:03

0:00:13

0:00:13

0:01:43

0:01:43