filmov

tv

G & M Code: CNC Lathe Programming by Hand - Vlog #91

Показать описание

CNC Machining - How to hand write a CNC lathe program using G & M Code.

CNC Machining is what we do. We are Experts and on this channel we are bringing our knowledge and experience to YOU. Want more? Learn CAD, CAM & CNC Machining through our FREE TITANS of CNC: Academy.

___

___

FREE CNC Machining Academy. Join the Revolution:

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

Follow our CEO, Titan Gilroy:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #kennametal

MB017E7JAFBH4VC

CNC Machining is what we do. We are Experts and on this channel we are bringing our knowledge and experience to YOU. Want more? Learn CAD, CAM & CNC Machining through our FREE TITANS of CNC: Academy.

___

___

FREE CNC Machining Academy. Join the Revolution:

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

Follow our CEO, Titan Gilroy:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #kennametal

MB017E7JAFBH4VC

G & M Code - Titan Teaches Manual Programming on a CNC Machine.

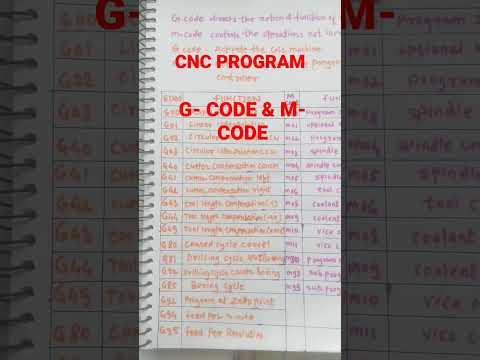

Cnc machine M code and G code #cnc machine #Gcode #Mcode #cnc

G codes and M codes for CNC programming | important G codes | Important M codes | #gcode #mcode

Understand G code for beginners Part 1

G & M Code: CNC Lathe Programming by Hand - Vlog #91

What are G & M Codes?

How to Master G Code for Crafting Exquisite Parts on CNC lathe#mechanical #metallurgy#programming

G -Code use in cnc machine#shorts #cnc #cncmachine

Big offer CNC book all India supply #bestcncbookalloverindia #latesttechnologycncbook #cncbooksell

g code and m code cnc programming #shorts #gcode #mcode #cnc

Mastering G Code CNC Basics #cnc

Knowing what code is used here can be called a master #CNC lathe #turn-milling #CNC programming

CNC Language Structure - G Code, M Code, and Programming Basics

Basic Movements with G-Code

Basic G-Code programming for CNC routers

G Code And M Codes In CNC

G74 in CNC | What is G90 in Fanuc | #simulator #boringOperations #groove_ing operation #shortvideo

G83 Code Tutorials, Face Drilling with a Better Chip Removal | CNC SMARTLATHE

cnc g code &easy language

This G-Code Cuts a Better Chip 😎

List of M - Codes for ALL CNC Machines

How to use G32 code of CNC lathe | CNC smartlathe

G and m code basics(1)

G- CODE & M- CODE || CNC MACHINE PROGRAMING|| ITI INSTRUCTOR EXAM PREPARATION#cbt2 #itiexam

Комментарии

0:26:32

0:26:32

0:00:20

0:00:20

0:08:47

0:08:47

0:42:11

0:42:11

0:19:39

0:19:39

0:00:29

0:00:29

0:00:11

0:00:11

0:00:16

0:00:16

0:00:41

0:00:41

0:01:01

0:01:01

0:00:22

0:00:22

0:00:19

0:00:19

0:06:21

0:06:21

0:08:32

0:08:32

0:23:43

0:23:43

0:00:59

0:00:59

0:00:16

0:00:16

0:00:09

0:00:09

0:00:16

0:00:16

0:00:36

0:00:36

0:05:51

0:05:51

0:00:19

0:00:19

0:00:42

0:00:42

0:00:15

0:00:15