filmov

tv

Preventative maintenance? Isn’t that a myth?

Показать описание

Preventative maintenance? Isn’t that a myth?

How to Make Preventative Maintenance Easy

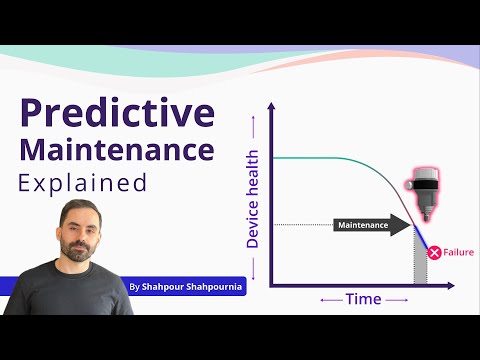

Predictive Maintenance Explained

Performing a Dock Leveler Preventive Maintenance Inspection

Preventative, Predictive & Breakdown Maintenance - What's the Difference?

The Case For Preventative Maintenance Part 1: If it Ain't Broke

Why Preventative Maintenance Will Save your Life - PMCS?

Preventative Maintenance Checks For Your Towable Vehicle -- My RV Works

Preventative Maintenance

How Often Should You Perform Preventative Maintenance on an Oil and Gas Well Site?

Preventive Maintenance Optimization

Basic preventative maintenance

What is Preventive Maintenance ?

Importance of Medical Imaging Preventive Maintenance

Preventative Maintenance...You Can Do It!

What is Predictive Maintenance?

Essential Guide to Preventative Maintenance for Steam Traps by UpKeep

What is preventive maintenance?

PA.I.B.K2 Pilot-Performed Preventative Maintenance

How preventative home maintenance can save you money

Three Tips to Figuring Out When and How to Perform Preventative Maintenance

5 Basic Computer Preventive Maintenance Tips You Don't Need IT's Help With

80 series Land Cruiser - Important Preventative Maintenance!

Preventive Maintenance! -- Toys won't last long if you don't do it....

Комментарии

0:02:58

0:02:58

0:03:30

0:03:30

0:07:26

0:07:26

0:01:10

0:01:10

0:05:04

0:05:04

0:04:15

0:04:15

0:07:16

0:07:16

0:15:45

0:15:45

0:00:59

0:00:59

0:03:52

0:03:52

0:11:27

0:11:27

0:15:49

0:15:49

1:21:51

1:21:51

0:01:37

0:01:37

0:02:01

0:02:01

0:19:00

0:19:00

0:03:10

0:03:10

0:01:11

0:01:11

0:02:06

0:02:06

0:02:22

0:02:22

0:04:01

0:04:01

0:04:30

0:04:30

0:13:36

0:13:36

0:02:18

0:02:18