filmov

tv

Predictive Maintenance Explained

Показать описание

▶ You can read the full post here

⌚Timestamps:

00:00 - Intro

00:33 - 1. Reactive maintenance

01:54 - 2. Preventive maintenance

02:37 - 3. Predictive maintenance

03:04 - Preventive maintenance vs. Predictive maintenance

03:39 - Utilizing Artificial Intelligence

05:19 - Applying predictive maintenance to the human body!

06:04 - Summary

=============================

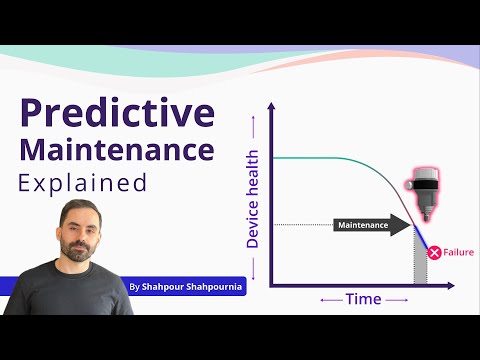

Every device has a point of failure. What does that mean? Well, a new device fresh from the manufacturer is healthy and problem-free. Due to wear and tear on the device as it ages, its health slowly deteriorates and eventually it fails.

At this point, you need to perform maintenance for the device to get it back to a healthy condition. There are three main types of maintenance: Reactive, preventive, and predictive.

1) With reactive maintenance, you simply wait until a device breaks down and then perform maintenance on that device.

That means that you wait until the device fails and requires maintenance and then react, hence reactive maintenance.

For example, let’s say that you have a microwave oven at home. You use it for a few years until it gets to the point of failure and It won’t turn on anymore.

In this case, you repair the microwave or buy a new one. But it may take a couple of days for you to either repair the microwave or buy a new one.

That means, with this wait and react way of maintenance, you may not be able to use your microwave for a couple of days which is not a big deal.

However, if the same thing happens in a big industrial enterprise like an oil refinery, there might be huge consequences.

2) With preventive maintenance, you try to perform maintenance for the device long before the device gets to the point of failure.

For example, you can check the pressure transmitter regularly and before it gets to the point of failure to make sure that there won’t be any sudden interruption to the industrial process.

However, this is not very cost-effective. Because by performing the maintenance early, you waste device life that is still usable.

This is the time that we could still use the device without any maintenance but now we’re losing that because of early preventing maintenance.

3) With predictive maintenance, you predict when the device fails and schedule maintenance just before that.

Following this process, you minimize the device or machine downtime and maximize its lifetime.

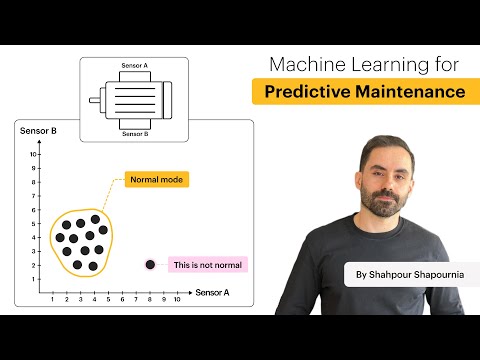

How can we predict when a device fails? Well, this is simply done using the previous data that we have collected from a similar device in the past.

For instance, with the pressure transmitter example, there are already thousands if not millions of similar devices installed all over the world from the same brand. By analyzing the available data from these current devices, we can pretty accurately predict when a similar device fails.

The fancy term that we currently use or maybe overuse for utilizing this data is AI or Artificial Intelligence.

But, the basic principle comes down to analyzing historic and current data and making intelligent decisions for the future.

One of these intelligent or smart decisions that we can make is to predict when a similar new device will fail in the future and perform maintenance right before that, hence predictive maintenance!

What if we could apply this whole concept of predictive maintenance to human body organs? I mean what if we could replace a heart before it fails for example?

Could we then live forever? What if aging is a disease? Consider how the world would change if we could live forever?

The plan that Elon Musk and SpaceX have started for making humans multi-planetary seems in line with living a considerably longer life.

=============================

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #maintenance #industry

Комментарии

0:07:26

0:07:26

0:06:03

0:06:03

0:02:28

0:02:28

0:05:09

0:05:09

0:00:49

0:00:49

0:02:43

0:02:43

0:19:00

0:19:00

0:07:01

0:07:01

0:00:32

0:00:32

0:01:25

0:01:25

0:06:40

0:06:40

0:05:18

0:05:18

0:05:33

0:05:33

0:01:01

0:01:01

0:01:16

0:01:16

0:01:21

0:01:21

0:00:41

0:00:41

0:08:25

0:08:25

0:09:10

0:09:10

0:03:00

0:03:00

0:15:06

0:15:06

0:03:29

0:03:29

0:03:29

0:03:29

0:02:03

0:02:03