filmov

tv

Fixing Electromagnetic Interference and Grounding a CNC

Показать описание

I determined that electrical interference is causing communication issues with the stepper motor encoders on my CNC. In this video I show you how I fixed this problem.

Fixing Electromagnetic Interference and Grounding a CNC

Electromagnetic Shielding 101 | How To Ground EMI Shielding Tape (Pt. 1)

Electromagnetic Interference & How to Reduce it

AEMC® - Reducing Noise Voltage/Broadband EMI In Shielded Cables

How Does Shielded Cable Reduce Electrical Noise? We Use a Plasma Ball to Find Out

Electromagnetic Shielding 101 | How To Ground EMI Shielding Tape (Pt. 2)

Grounding and Shielding of electric circuits

Audio RF interference and ground loops

Here’s A BETTER Way To Protect Circuits From EMI/RFI 📡🥽 (Part 1)

Tips for Proper Wiring and Reducing EMI (Noise) - ADVANCED Motion Controls

Checking for proper grounding for a PC based CNC controller

Eliminating RFI and Ground Loops - Sound Speeds

EMI shielding and grounding to reduce electrical noise interference to KiwiSDR receiver

Electromagnetic Shielding 101 | How To Ground EMI Shielding Tape (Pt. 3)

What is an H Shield and how to fix it? - Electromagnetic Interference (EMI) Educational Series

EMC - Proper Grounding to Reduce EMI

Power Wire Electromagnetic interference with RCA Fix

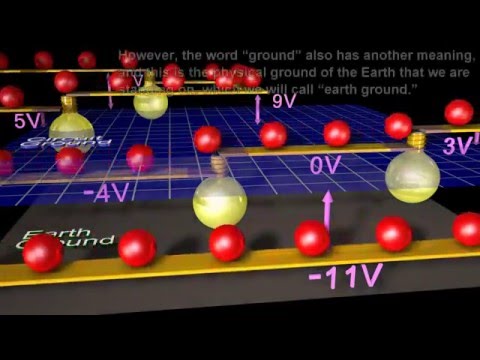

Ground Wire Explained

5 Tips for Reducing Electromagnetic Interference (EMI) in VFD's

RF (EMI) interference in action

EMI Shield Demo

EMC Part 38. What is Ground Loop and how is Created Unintentionally. How to Break the Ground Loop.

How to fix Ground Noise | Guitar Tech Tips | Ep. 8 | Thomann

20M Singleside Conductive Copper Foil TapeMask Shield Eliminate EMI Anti-static Repair Adhesive Tape

Комментарии

0:09:41

0:09:41

0:00:36

0:00:36

0:07:25

0:07:25

0:01:39

0:01:39

0:02:56

0:02:56

0:00:18

0:00:18

0:07:26

0:07:26

0:04:05

0:04:05

0:00:45

0:00:45

0:11:04

0:11:04

0:02:16

0:02:16

0:13:56

0:13:56

0:04:11

0:04:11

0:00:22

0:00:22

0:01:40

0:01:40

0:11:44

0:11:44

0:06:22

0:06:22

0:03:33

0:03:33

0:03:13

0:03:13

0:00:13

0:00:13

0:04:39

0:04:39

0:08:06

0:08:06

0:05:45

0:05:45

0:00:27

0:00:27