filmov

tv

FIELD TRIP-MY OLD SEARS DRILL PRESS #832 tubalcain

Показать описание

Join me on a short field trip to my friend's shop where I become reacquainted with my 1971 Craftsman drill press. I review it's strong points & it's frailties.

Also, watch this related video. ANOTHER DRILL PRESS FOLLOWED ME HOME #831 tubalcain

Please LIKE and SUBSCRIBE

#drillpress#atlas#craftsman#clausing#walkerturner#delta

Also, watch this related video. ANOTHER DRILL PRESS FOLLOWED ME HOME #831 tubalcain

Please LIKE and SUBSCRIBE

#drillpress#atlas#craftsman#clausing#walkerturner#delta

FIELD TRIP-MY OLD SEARS DRILL PRESS #832 tubalcain

Secret for Drill Bits revealed #shorts

Vintage craftsman drill press repair, stuck quill lock

POV: you’re 6’9” 400 pounds and booked the middle seat

BARBER CUTS OFF LICE!!!! MUST WATCH

This mom had an amazing idea for her son’s graduation party ❤️

If teachers became their students!

He is singing after breaking his foot?! — This will do it

mrpete222 Swaps a DP for a LISLE DRILL GRINDER long ver. tubalcain

7th grade first year ever running track

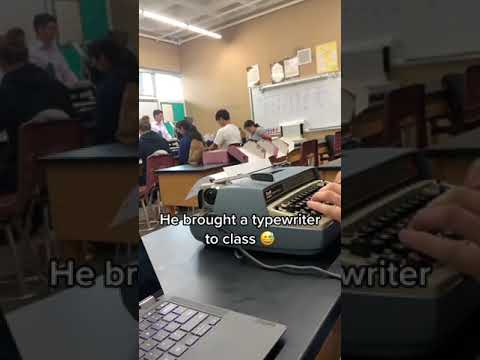

His laptop died so he used his TYPEWRITER. 😭🤷♂️ #shorts

Craftsman 15' Drill Press Repair

ANOTHER DRILL PRESS FOLLOWED ME HOME #831 tubalcain SEARS craftsman

Does This 100 Year Old Digging Technique Make Any Sense? #shorts

Pledge Allegiance- Mrs. Cozzolino’s class

serial killers on why they killed #shorts

Handyman's Don't Want You To Know This! Tips & Hacks That Work Extremely Well

Seized Drill Press Rebuild | Craftsman 113

How to SINK your Boat #6 | Wavy Boats | Haulover Inlet

Video on Tik Tok. #apprentice apprentice #mechanicgirl #cargirl #snapontools #fyp #snapon

Straight up the Chute! #SandHollow #Jeep #Offroad #Shorts

WE FOUND OUT WHAT’S WRONG WITH HER LIPS!! 😲

Antique 1950's Drill Press. 103. Dunlap/Craftsman/King Seeley. Back into service. Restore

Jeffrey Dahmers Terrifying Last Worlds In His Last Interview Ever #shorts #trending

Комментарии

0:22:41

0:22:41

0:00:24

0:00:24

0:08:07

0:08:07

0:00:18

0:00:18

0:00:15

0:00:15

0:00:20

0:00:20

0:00:25

0:00:25

0:00:22

0:00:22

0:35:06

0:35:06

0:00:21

0:00:21

0:00:42

0:00:42

0:23:58

0:23:58

0:20:10

0:20:10

0:00:35

0:00:35

0:00:27

0:00:27

0:00:31

0:00:31

0:05:00

0:05:00

0:16:25

0:16:25

0:00:30

0:00:30

0:01:01

0:01:01

0:00:16

0:00:16

0:00:35

0:00:35

0:27:30

0:27:30

0:00:49

0:00:49