filmov

tv

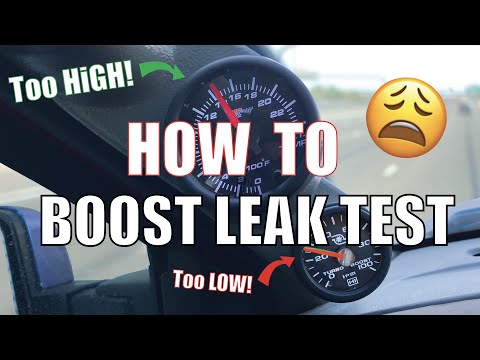

7.3 Powerstroke Boosts Leaks, Up-Pipes, and Exhaust Leaks Fixed!

Показать описание

A lot of people have issues with boost and exhaust leaks on their 7.3 turbos. This will rob power and make your turbo not run right. Even small leaks can SEEM to run right, but you are still losing out!

Here is a few tricks to help fix the issue. Lets fix them!

-------------------------------------------------------------------------------------------------------------------------

Subscribe to @KCTURBOS

Here is a few tricks to help fix the issue. Lets fix them!

-------------------------------------------------------------------------------------------------------------------------

Subscribe to @KCTURBOS

7.3 Powerstroke Boosts Leaks, Up-Pipes, and Exhaust Leaks Fixed!

Boost leak testing a 7.3 Powerstroke

2001 F350 7.3 - RiffRaff Up-Pipes Install - Stock up pipes leaking and falling apart JUNK!! SP

Got Boost Leaks? WATCH THIS!!

Boost Leak Test Your Diesel Truck

7.3 Powerstroke Diesel Quick discussion regarding up-pipes and y pipes

2001 F350 7.3 - RiffRaff Up-Pipes Install - Stock up pipes leaking and falling apart JUNK!! F250

7.3 Repairs: Boost Leak Fix, Fuel Filter and Lights

7.3L Super Duty Turbo, Pedestal, and Up Pipe Replacement, and EBPV Delete

7.3 POWERSTROKE UP PIPE REMOVAL / INSTALL 🛻🎥🟢🟡🔴🟢

Common 7.3L Boost Leaks! (And how to fix them)

Leaky up pipes in 7.3 Powerstroke

7.3 POWERSTROKE WASTEGATE CONTROL VALVE ...............................

Turbo Pedestals for 7.3L Powerstroke 101

7.3 POWER STROKE O RING NO LEAK TRICK.....................

Project PSD Part 12: Boost Leak Test

OBS Up-Pipe Proper Installation - 7.3 Powerstroke

Boost leak test obs 7.3 powerstoke

Ford 7.3 Powerstroke Common problems part 3: Leaking Up Pipes

1997 Ford 7.3 Bad up pipe donuts

5 Cheap 7.3 powerstroke upgrades

7.3 PowerStroke 400/400’s and stainless 5 blade s480

XDP 7.3 Bellowed Up Pipes & DEI Titanium Wrap

2001 F350 7.3 Powerstroke - 18 psi to 25 psi free mod - Let’s see if she’s faster ??

Комментарии

0:04:45

0:04:45

0:03:43

0:03:43

0:24:49

0:24:49

0:01:33

0:01:33

0:05:26

0:05:26

0:05:25

0:05:25

0:11:57

0:11:57

0:10:17

0:10:17

0:22:59

0:22:59

0:30:13

0:30:13

0:05:19

0:05:19

0:00:09

0:00:09

0:08:22

0:08:22

0:04:34

0:04:34

0:31:25

0:31:25

0:04:27

0:04:27

0:09:30

0:09:30

0:02:56

0:02:56

0:07:04

0:07:04

0:00:13

0:00:13

0:05:54

0:05:54

0:00:13

0:00:13

0:07:03

0:07:03

0:10:06

0:10:06