filmov

tv

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

Показать описание

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

===

0:00 - 0:16: Intro

0:17 - 5:29: Raptor 3

5:30 - 9:23: a shockwave to Nasa, Raptor 3 vs RS - 25

===

#Q88M #q88m #spacex #starship #elonmusk #nasa

===

SOURCES OF IMAGES AND VIDEOS:

===

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

It happened!

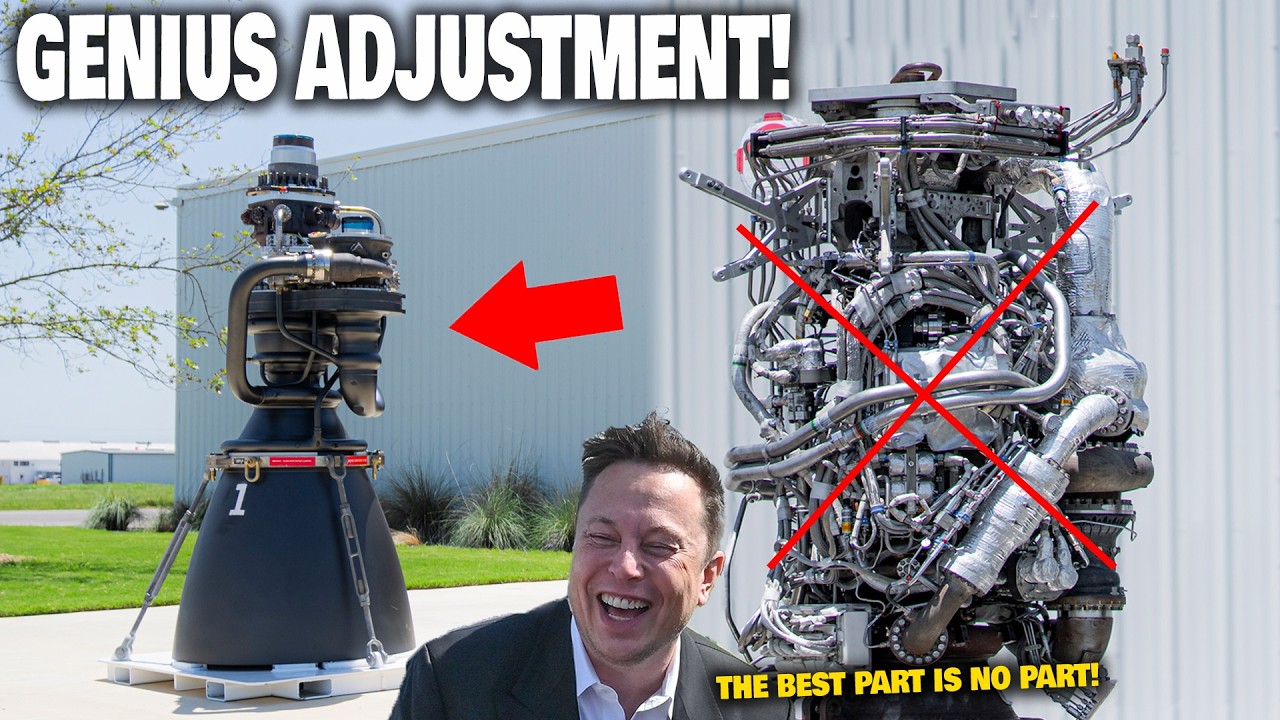

Elon Musk has just dropped a bombshell of a new clean Raptor 3. For the first time, we’re seeing the Raptor 3 in the flesh - no more slideshow renderings - and it’s got the entire community buzzing with excitement.

Especially, it has made the whole Nasa and their big brains shocking!

Let’s find out in today’s episode!

First, let's take a closer look at the design of the Raptor 3. At first glance, I thought it was a 3D render because it's just so sleek. The design of the Raptor 3 is truly simple and elegant, with most of the flanges and manifolds significantly minimized.

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

So, where did all those complex valves and pipes go? Many of them have been eliminated, and the remaining ones are integrated directly into the engine's body. There could be many flow paths we can't see inside, which help reduce the combustion chamber temperature and limit the heat transfer between engines.

With this method, they've reduced the dry weight of the engine, and it doesn't require any heat shielding or fire suppression systems. This is called active cooling.

So now, instead of installing thousands of small parts, SpaceX can now assemble a few larger but more complex components. Despite the complexity of each big one, the production speed of complex engine parts can still be optimized further. It's likely that SpaceX uses laser 3D printing technology to create large parts of the engine, allowing for the rapid production of prototypes.

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

For mass production and cost reduction, these large parts might be replaced by more intricate castings. Complex casting allows for higher production volumes and reduced costs compared to laser printing. If I'm not mistaken, Tesla has been using high - pressure casting technology to create parts from aluminum. SpaceX might adopt and adjust Tesla's casting techniques for the Raptor engine manufacturing to facilitate mass production.

The arrival of the Raptor 3 engine has sparked an incredible wave of excitement within the space tech community, but it hasn't been without its controversies. Notably, it seems to have reignited the fierce comparison between the Raptor 3 and its rival, Blue Origin's BE-4, within the community.

Tory Bruno, CEO of United Launch Alliance (ULA), expressed his dissatisfaction in a tweet: They have done an excellent job making the assembly simpler and more producible. So, there is no need to exaggerate this by showing a partially assembled engine without controllers, fluid management, or TVC systems, then comparing it to fully assembled engines that do."

===

0:00 - 0:16: Intro

0:17 - 5:29: Raptor 3

5:30 - 9:23: a shockwave to Nasa, Raptor 3 vs RS - 25

===

#Q88M #q88m #spacex #starship #elonmusk #nasa

===

SOURCES OF IMAGES AND VIDEOS:

===

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

It happened!

Elon Musk has just dropped a bombshell of a new clean Raptor 3. For the first time, we’re seeing the Raptor 3 in the flesh - no more slideshow renderings - and it’s got the entire community buzzing with excitement.

Especially, it has made the whole Nasa and their big brains shocking!

Let’s find out in today’s episode!

First, let's take a closer look at the design of the Raptor 3. At first glance, I thought it was a 3D render because it's just so sleek. The design of the Raptor 3 is truly simple and elegant, with most of the flanges and manifolds significantly minimized.

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

So, where did all those complex valves and pipes go? Many of them have been eliminated, and the remaining ones are integrated directly into the engine's body. There could be many flow paths we can't see inside, which help reduce the combustion chamber temperature and limit the heat transfer between engines.

With this method, they've reduced the dry weight of the engine, and it doesn't require any heat shielding or fire suppression systems. This is called active cooling.

So now, instead of installing thousands of small parts, SpaceX can now assemble a few larger but more complex components. Despite the complexity of each big one, the production speed of complex engine parts can still be optimized further. It's likely that SpaceX uses laser 3D printing technology to create large parts of the engine, allowing for the rapid production of prototypes.

SpaceX Just Revealed NEW Raptor 3.0 Design Upgrade Shocked NASA's Scientist…

For mass production and cost reduction, these large parts might be replaced by more intricate castings. Complex casting allows for higher production volumes and reduced costs compared to laser printing. If I'm not mistaken, Tesla has been using high - pressure casting technology to create parts from aluminum. SpaceX might adopt and adjust Tesla's casting techniques for the Raptor engine manufacturing to facilitate mass production.

The arrival of the Raptor 3 engine has sparked an incredible wave of excitement within the space tech community, but it hasn't been without its controversies. Notably, it seems to have reignited the fierce comparison between the Raptor 3 and its rival, Blue Origin's BE-4, within the community.

Tory Bruno, CEO of United Launch Alliance (ULA), expressed his dissatisfaction in a tweet: They have done an excellent job making the assembly simpler and more producible. So, there is no need to exaggerate this by showing a partially assembled engine without controllers, fluid management, or TVC systems, then comparing it to fully assembled engines that do."

Комментарии

0:09:32

0:09:32

0:11:42

0:11:42

0:07:19

0:07:19

0:22:12

0:22:12

0:11:26

0:11:26

0:08:55

0:08:55

0:11:00

0:11:00

0:18:18

0:18:18

0:21:11

0:21:11

0:08:51

0:08:51

0:10:48

0:10:48

0:09:20

0:09:20

0:09:57

0:09:57

0:09:11

0:09:11

0:25:37

0:25:37

1:00:01

1:00:01

0:11:20

0:11:20

0:11:02

0:11:02

0:22:18

0:22:18

0:09:24

0:09:24

0:20:41

0:20:41

0:24:19

0:24:19

0:21:04

0:21:04

0:12:11

0:12:11