filmov

tv

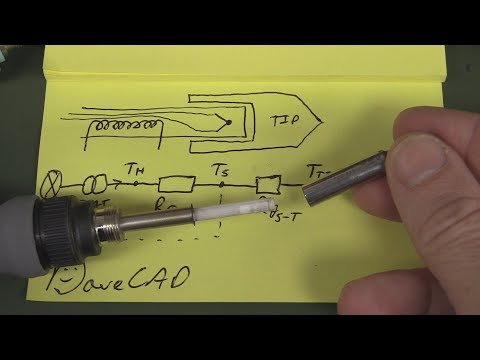

EEVblog #183 - Soldering Tutorial Part 2

Показать описание

A beginners guide to learning how to hand solder.

Remember to watch the first part, which is all about the tools:

If you find my content useful you may consider supporting me on Patreon or via Crypto:

BTC: 33BsprBQNBtHuVzVwDmqWkpDjYnCouwASM

ETH: 0x68114e40ff4dcdd384750500501e20acf3875f8c

BCH: 35n9KBPw9T7M3NGzpS3t4nUYEf9HbRmkm4

USDC: 0x68114e40ff4dcdd384750500501e20acf3875f8c

LTC: MJfK57ujxy55su4XicVGQc9wcEJf6mAoXF

Remember to watch the first part, which is all about the tools:

If you find my content useful you may consider supporting me on Patreon or via Crypto:

BTC: 33BsprBQNBtHuVzVwDmqWkpDjYnCouwASM

ETH: 0x68114e40ff4dcdd384750500501e20acf3875f8c

BCH: 35n9KBPw9T7M3NGzpS3t4nUYEf9HbRmkm4

USDC: 0x68114e40ff4dcdd384750500501e20acf3875f8c

LTC: MJfK57ujxy55su4XicVGQc9wcEJf6mAoXF

EEVblog #183 - Soldering Tutorial Part 2

EEVblog #180 - Soldering Tutorial Part 1 - Tools

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount

LIVE Soldering

EEVblog #997 - How To Solder Surface Mount Components

EEVblog #184 - Open Hardware Multimeter Concept

EEVblog #181 - Dead Bug Prototype Soldering

EEVblog #434 - SMD Thermal Pad & Drag Soldering Tutorial

SOLDER PASTE reflow on paper 138C LeadFree and 183C 63/37 No clean solder paste CyberDocLLC.com

How to solder components using hot air without them blowing away

SMT Soldering - Hand soldering trick

EEVblog #1065 - Soldering Iron Power Delivery Explained

CB2 Microcomputer Kit Assembly & Soldering

EEVblog #431 - PCB Wave Soldering

EEVblog #1064 - Soldering Irons OLD vs NEW

Electronics: Tutorial Soldering Iron Tips

EEVblog #397 - Turnigy Accucell 6 Charger Teardown

EEVblog #688 - How To Rework Solder SMD Chips - BTTF Time Circuits Repair!

EEVblog #298 - Dave's Decade Digit Display - USB Supply Part 3

Soldering Tutorial for Beginners: Five Easy Steps

EEVblog #1373 - DIY PCB Photograhy LED Light Box - Part 2

Basic Skills!: Basic Soldering

Soldering 101

Basic Soldering Technique

Комментарии

0:34:06

0:34:06

0:27:14

0:27:14

0:39:56

0:39:56

1:12:33

1:12:33

0:17:37

0:17:37

0:17:38

0:17:38

0:11:31

0:11:31

0:18:12

0:18:12

0:15:39

0:15:39

0:09:03

0:09:03

0:00:25

0:00:25

0:23:04

0:23:04

0:36:31

0:36:31

0:06:45

0:06:45

0:26:11

0:26:11

0:08:34

0:08:34

0:33:50

0:33:50

0:24:52

0:24:52

0:21:38

0:21:38

0:03:57

0:03:57

0:19:48

0:19:48

0:02:03

0:02:03

0:03:26

0:03:26

0:04:59

0:04:59