filmov

tv

Woodshop Transformation: How to Build a Wooden Table Saw for Compact Workshops

Показать описание

In this video, we embark on an exciting journey to transform a small woodworking workshop. Watch as we design and build a custom-made table saw entirely from wood. This DIY project is perfect for those with limited space, allowing you to optimize your woodworking area and enhance your craftsmanship. Join us as we explore the step-by-step process of creating a homemade table saw that's both functional and tailored to your needs. Whether you're a beginner or a seasoned woodworker, this video offers valuable insights and inspiration for enhancing your woodworking setup.

Do you have an idea, a project to work on or a proposal? Please leave a comment below. We will do it for you.

★Thank for watching!

#WoodworkingSkill

Do you have an idea, a project to work on or a proposal? Please leave a comment below. We will do it for you.

★Thank for watching!

#WoodworkingSkill

Woodshop Transformation: How to Build a Wooden Table Saw for Compact Workshops

11 Simple Ways to Organize Any Workshop

EPIC Woodshop Transformation! Building my dream craft space.

Epic Wall Transformation in The Dream Shop!

The Transforming Table 2.0. #woodworking #diy #build #transformation

Man Builds Amazing DIY Container Workshop | Start to Finish by @BendheimBoards

Upgrade Superman Crafting Carpenter: Great Waste Wood Transformation Projects - Woodworking Projects

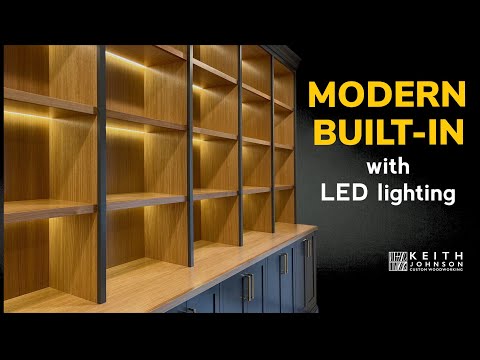

How to transform your home with custom built-ins.

'Custom Cabinet Reveal: Transformation Complete!'

Ultimate Mobile Garage Storage || Transform Your Garage

INCREDIBLE DIY Backyard Transformation

You see an old tire 🚗 I see an amazing piece of garden furniture! 🏡

DIY backyard bliss: A cozy transformation anyone can do! 😁

Awesome Woodworking Hack – How to Transform Your Router Table into a Jointer!

Tiny garden transformation part 1

13 Easy Ways to Organize a Messy Woodworking Shop

Going back in time ⏰ to 1974 #restoration #midcentury #wood #vintage #transformation #before #after...

Amazing Wood Transformation😥❤️#shorts

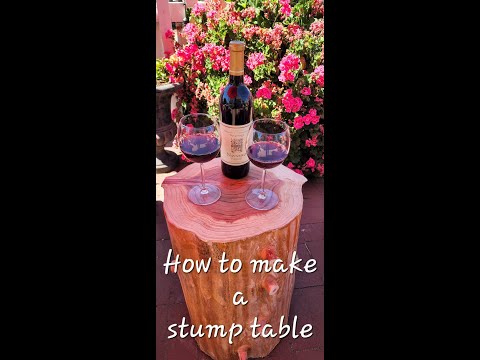

Transform a TREE STUMP into a STUNNING TABLE for Under $10!

Build a saw-bench. Transform your woodwork.

Waterfall Art Deco buffet transformation #furnitureflip #furniture #stepbystep #transformation #diy

89 years ago…🕰️VS. NOW? #furniture #restoration #wood #work #vintage #transformation #handmade #old...

Single Car Garage Woodshop Transformation #shorts

Transform this empty space #diy #cabinet #woodworking #woodwork #homedecor #custom #design #maker

Комментарии

0:50:19

0:50:19

0:10:56

0:10:56

0:19:39

0:19:39

0:12:32

0:12:32

0:00:13

0:00:13

0:22:03

0:22:03

0:44:44

0:44:44

0:29:49

0:29:49

0:00:59

0:00:59

0:22:30

0:22:30

0:22:52

0:22:52

0:00:24

0:00:24

0:01:00

0:01:00

0:00:46

0:00:46

0:52:46

0:52:46

0:14:56

0:14:56

0:00:58

0:00:58

0:00:44

0:00:44

0:00:54

0:00:54

0:13:26

0:13:26

0:00:36

0:00:36

0:00:38

0:00:38

0:00:58

0:00:58

0:00:41

0:00:41