filmov

tv

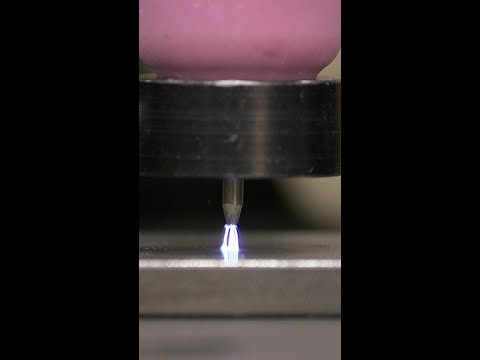

How to weld 6G Copper Nickel Pipe Test Guide for Navy Shipyards

Показать описание

This is a guide to help someone prepare for the copper nickel 6g pipe test 90/10 with 1/16 RN67 filler wire.

How to weld 6G Copper Nickel Pipe Test Guide for Navy Shipyards

HOW TO TIG WELD COPPER PIPE - TIPS AND TRICKS

TIG weld 6G🤨🧐🧐root pasd welding

Brazing copper

Walking The Root In | TIG Welding

How to Weld Copper | TIG Time

TIG Welding Copper to Steel HOW TO

#tigwelding test 2” pipe copper 6g # position #trending

What is the Best F4X Welding Technique for Beginners?

6g 6' sch 40 tig all the way out #pipewelding #carbonsteel #tigwelding #welding

I Taught Myself How to Tig Weld Copper - Here are the RESULTS 🤔#shorts #welding

How to Weld 7030 4 Inch Copper Nickel Pipe Part 1

6G Tig welding done correct!

6G pipe Lloyds100% X-ray#tig #tigwelding #mechanical #pipewelder #soldadura #gas #perfect #factory

MIG welding a root , fill and cap.

Freehand Tig Root Pass VS Walking The Cup Root Pass

Tig welding Moving ❤️#tig #mig #shorts #views #sunscribe

Monel Stick Welding on a Copper-Nickel Plate | First Time Welding it🤨

Techniques for welding round pipes

Beginner TIG welders NEED to know this...

tig Welding - how to Welding 6g - tig pipe Welding

How To Braze Copper Pipe Like A Pro (HVAC Refrigerant Lines)

Tig Welding, How to pass a 6G - 6' Stainless Steel Schedule 10 Pipe Test

6GR welding position in TKY and T- joints ! Smaw !

Комментарии

0:07:15

0:07:15

0:05:56

0:05:56

0:00:30

0:00:30

0:00:30

0:00:30

0:00:13

0:00:13

0:04:07

0:04:07

0:15:46

0:15:46

0:00:28

0:00:28

0:17:55

0:17:55

0:00:19

0:00:19

0:00:16

0:00:16

0:35:51

0:35:51

0:00:23

0:00:23

0:00:18

0:00:18

0:00:06

0:00:06

0:00:20

0:00:20

0:00:13

0:00:13

0:14:01

0:14:01

0:00:09

0:00:09

0:00:18

0:00:18

0:00:16

0:00:16

0:06:43

0:06:43

0:34:24

0:34:24

0:00:16

0:00:16