filmov

tv

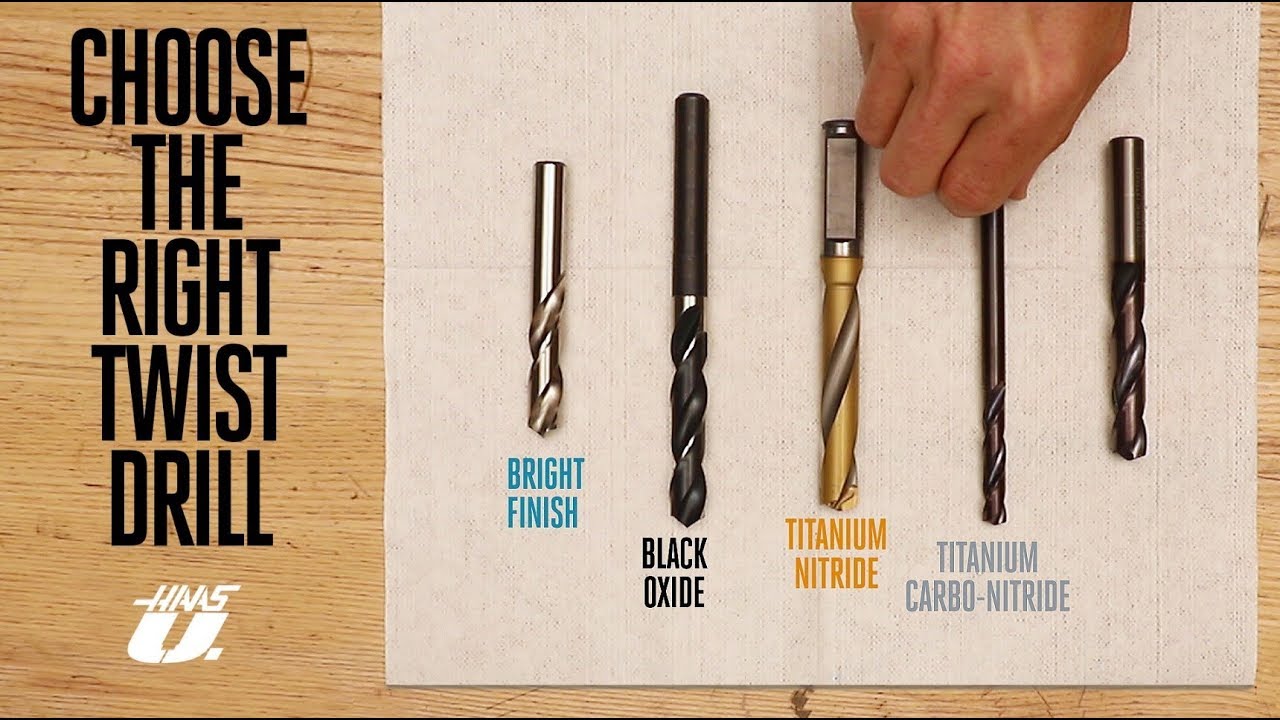

Basics of Drill Selection - Haas University

Показать описание

In the inaugural episode of Haas University (Haas U), Manufacturing Engineer Andrew Harnett guides you through the basics of selecting the proper twist drill. You'll learn about the pros and cons of choosing high-speed steel, cobalt, and carbide, as well as advice on coatings, drill point and flute geometry, and more. How many times have you just grabbed the closest drill without really knowing if it's the right tool for the job? After watching this video that should hopefully be less of a problem!

If you enjoyed this video, please hit the like button and share it with a friend who’ll find it helpful . . . and thanks!

Follow Haas:

If you enjoyed this video, please hit the like button and share it with a friend who’ll find it helpful . . . and thanks!

Follow Haas:

Basics of Drill Selection - Haas University

Beginners' Guide to Drill Bits and Driver Bits

Choosing The Right Size Pre Drill Bit | Beginner

5 Drill Features Everyone Should Know

Cordless Drill Basics | Beginner

5 Amazing and Useful INGCO Drill Bits | Basics of Drill Selection | Drill Bit Guide

When To Use an Impact Driver VS Drill: The ULTIMATE Guide

Basics of Drill Bits - TEACH Construction Trades Training Series

How to Install a Wall Plug. How to select Drill bit

Types of Drill Bits - Wood, Masonry, Metal

BEGINNER'S GUIDE TO USING A DRILL - STEP-BY-STEP

How to Use a Power Drill and Impact Driver | WOODWORKING BASICS

How to Buy a Drill? | Drill Basics & Recommendations

How to tell if drill bit is for metal or wood |

Drill Selection 101: How to Pick the Right Drill? | Machine Shop Talk Ep. 111

How To Choose A Cordless Drill or Impact Driver - Ace Hardware

What Do The Settings On A DeWALT Drill Mean

Types of Drill Bits and Their Uses | Wood | Concrete | Metal Drill Bits

SOLID CARBIDE DRILL VS HSS DRILL - HOW TO SELECT DRILLS - BEST PERFORMANCE DRILL

Drill Bits #shorts

Drill Basics Part 1

The Most MISUNDERSTOOD Feature On Your Drill

Learn To Use Your Drill like a Pro! (Settings On A Makita Drill)

What's a drill press? Do you need one? | Mere Mini

Комментарии

0:14:36

0:14:36

0:15:38

0:15:38

0:03:33

0:03:33

0:08:35

0:08:35

0:03:30

0:03:30

0:02:13

0:02:13

0:13:28

0:13:28

0:13:32

0:13:32

0:02:16

0:02:16

0:00:56

0:00:56

0:16:13

0:16:13

0:14:40

0:14:40

0:04:23

0:04:23

0:01:25

0:01:25

0:14:41

0:14:41

0:03:39

0:03:39

0:03:46

0:03:46

0:01:29

0:01:29

0:03:17

0:03:17

0:00:31

0:00:31

0:14:03

0:14:03

0:13:41

0:13:41

0:02:31

0:02:31

0:02:40

0:02:40