filmov

tv

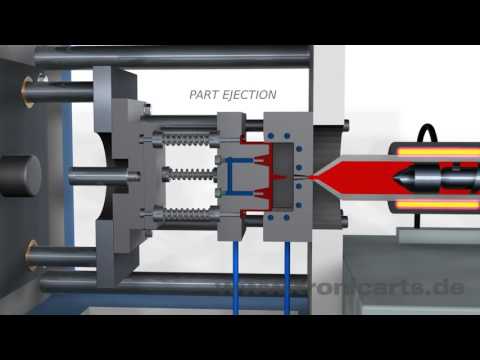

Simulation Flow 'Plastic Injection Mold' e.g. 1

Показать описание

Teknopres engineers describe how they used a highly accurate casting simulation program for filling, solidification, and stress analysis to complete successful injection molding / high pressure die casting projects.

As the industrial age progressed, there was a need for industrial designers to create products with increased complexity. Mold-designing technologies have developed rapidly to accommodate this need.

Design is an important preliminary step in the manufacturing process, but it is just as important to evaluate any design that will be realized by a mold. As with any design, time and effort should be spent on evaluating the viability of the design before proceeding.

# Step 1: Determine what type of mold it will be

# Step 2: Determine whether or not this mold has been designed before

# Step 3: Determine what is to be manufactured using this mold

# Step 4: Determine what type of material will be used in production

# Step 5: Consider how much time is needed for each production cycle

Channel Description:

Teknopres Design Academy is the go-to resource for anyone who wants to learn how to develop the best die casting tools.

We're committed to teaching you the skills you need to innovate at an industrial level,

so that you can design your own molds and dies.

In this tutorial we may use some of the below programs:

1.CAD CAM AUTODESK INVENTOR

2.CAD CAM AUTODESK FUSION 360

3.CAD CIMATRON CAM GibbsCAM

4.CAD CAM SOLIDWORKS

5.FLOW ANALYSIS : Autodesk Moldflow / Autodesk Moldflow ADVISER

6.FLOW ANALYSIS : Solidworks Simulation

7.FLOW ANALYSIS : Altair Inspire Mold / Altair Inspire Cast / Inspire Form

As the industrial age progressed, there was a need for industrial designers to create products with increased complexity. Mold-designing technologies have developed rapidly to accommodate this need.

Design is an important preliminary step in the manufacturing process, but it is just as important to evaluate any design that will be realized by a mold. As with any design, time and effort should be spent on evaluating the viability of the design before proceeding.

# Step 1: Determine what type of mold it will be

# Step 2: Determine whether or not this mold has been designed before

# Step 3: Determine what is to be manufactured using this mold

# Step 4: Determine what type of material will be used in production

# Step 5: Consider how much time is needed for each production cycle

Channel Description:

Teknopres Design Academy is the go-to resource for anyone who wants to learn how to develop the best die casting tools.

We're committed to teaching you the skills you need to innovate at an industrial level,

so that you can design your own molds and dies.

In this tutorial we may use some of the below programs:

1.CAD CAM AUTODESK INVENTOR

2.CAD CAM AUTODESK FUSION 360

3.CAD CIMATRON CAM GibbsCAM

4.CAD CAM SOLIDWORKS

5.FLOW ANALYSIS : Autodesk Moldflow / Autodesk Moldflow ADVISER

6.FLOW ANALYSIS : Solidworks Simulation

7.FLOW ANALYSIS : Altair Inspire Mold / Altair Inspire Cast / Inspire Form

Комментарии

0:00:14

0:00:14

0:00:09

0:00:09

0:01:01

0:01:01

0:00:23

0:00:23

0:00:48

0:00:48

0:00:11

0:00:11

0:00:32

0:00:32

0:30:16

0:30:16

0:02:59

0:02:59

0:34:28

0:34:28

0:00:32

0:00:32

0:12:16

0:12:16

0:00:27

0:00:27

0:49:13

0:49:13

0:00:17

0:00:17

0:14:13

0:14:13

0:00:16

0:00:16

0:04:31

0:04:31

0:03:04

0:03:04

0:21:43

0:21:43

0:00:54

0:00:54

0:00:54

0:00:54

0:06:45

0:06:45

0:22:31

0:22:31