filmov

tv

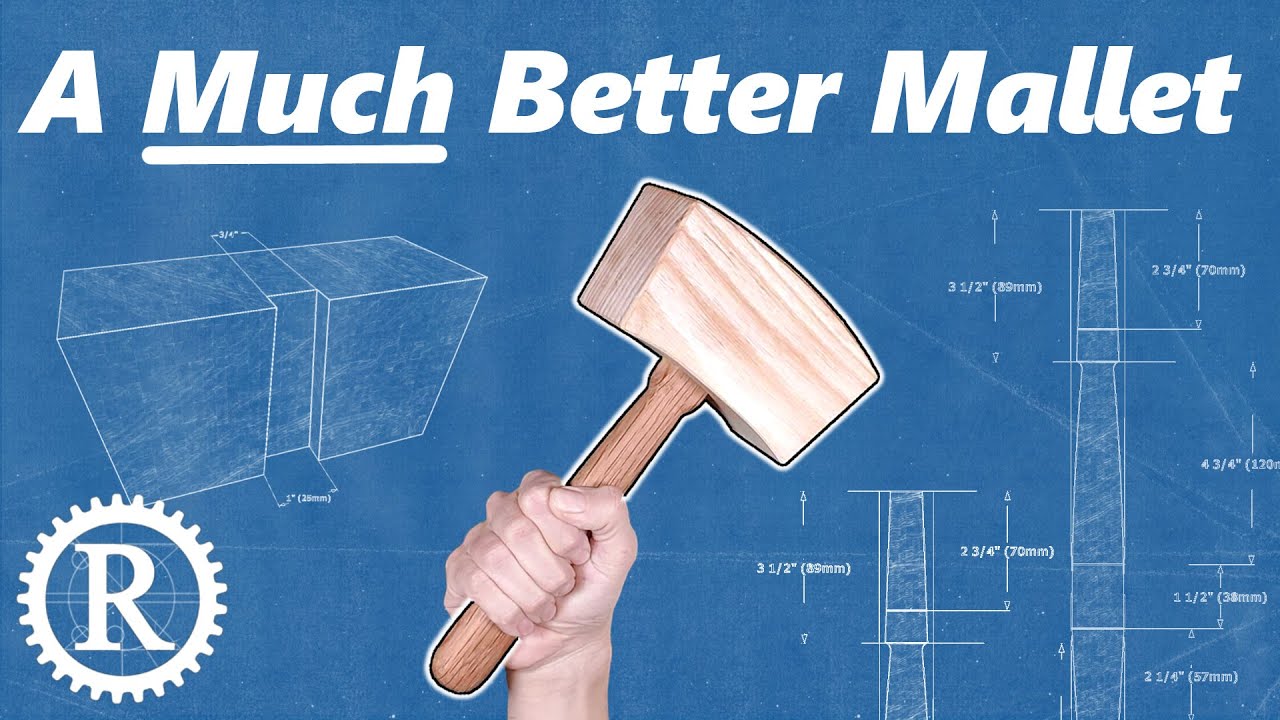

Build this amazing traditional mallet

Показать описание

Build your own copy of a handy and ergonomic historical joiner's mallet.

My previous mallet videos:

Tools in this build (affiliate):

(I use a vintage one, but the new ones are excellent, and expensive.)

(I use a vintage one, but this one is recommended.)

Follow me on Instagram: @rexkrueger

My previous mallet videos:

Tools in this build (affiliate):

(I use a vintage one, but the new ones are excellent, and expensive.)

(I use a vintage one, but this one is recommended.)

Follow me on Instagram: @rexkrueger

Build this amazing traditional mallet

Beginner Woodwork Project - Making a Scrap Wood Mallet

The Glove Woodworking Mallet

How to make a Joiners Mallet (part 1) | Paul Sellers

How to Make a Woodworking Mallet || DIY Mallet

Perfect Mallet

Wooden Mallet Made From 100% Firewood!

How to Make a Joiners Mallet, Building A First Woodworking Hand Tool

Why do we write Right to Left? #writing #study #shortsfeed

The Prefect Mallet

Make a mallet with THREE simple tools

every woodworker needs a dead blow mallet #woodworking

Strike your Chisel with a Hammer? or Mallet? #carpentry #diy #woodwork #howto #tooltips #wood

103 – Awesome new Thor's Hammer Woodworking Mallet design!

Carved Joiners Mallet Made From Oak Pallet Wood. A Mallet Out Of Pallet.

Make A MALLET (That Will Last A Lifetime)

How To Make A Wooden Mallet

How to Make a Small Wooden Mallet for Furniture Making

Making a Badass Woodworking Mallet

Woodworking DIY: How to Build Your Own Mallet from Scraps!

Making a Simple Mallet for Woodworking - Spalted Maple and Ash - Hand Tools

Martinez Full Titanium Hammer

My Best Wood Mallet Yet - How to Make Mallet on CNC | ToolsToday Video

Forging my Sons first hammer!🔥 #blacksmith #hammer #traditional #craft #fatherandson #diy #ireland...

Комментарии

0:21:06

0:21:06

0:10:12

0:10:12

0:14:24

0:14:24

0:33:20

0:33:20

0:07:45

0:07:45

0:10:34

0:10:34

0:07:34

0:07:34

0:06:26

0:06:26

0:00:45

0:00:45

0:11:04

0:11:04

0:15:34

0:15:34

0:00:43

0:00:43

0:00:48

0:00:48

0:17:50

0:17:50

0:18:52

0:18:52

0:11:02

0:11:02

0:07:15

0:07:15

0:23:34

0:23:34

0:04:19

0:04:19

0:15:09

0:15:09

0:08:58

0:08:58

0:00:18

0:00:18

0:06:53

0:06:53

0:01:01

0:01:01