filmov

tv

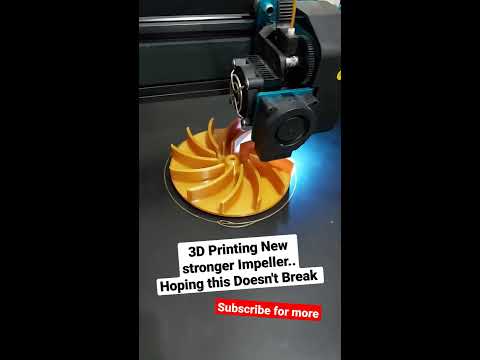

DIY 3D Printed Vacuum Impellers

Показать описание

Cyclone song by Colin Fox AKA TRUCK DADDY BEATS

IG: danielriley_

DIY 3D Printed Vacuum Impellers

3D Printed Turbo Impeller VS Dyson Motor

My Last Chance to OVERPOWER my Vacuum! (Homemade Turbine V2)

I tried OVERPOWERING my Vacuum! (Homemade Turbine)

DIY 3D Printer filament storage vacuum pump

DIY DUST COLLECTOR IMPELLER

I 3D Printed a Compressor that ACTUALLY WORKS (but you've never heard of this design)

DIY 3D printed vacuum cleaner build and testing

Designing and Prototyping a Centrifugal Blower.

380W 3D Printed vacuum cleaner

3D Printed Dyson Cyclone V10 Animal Attachment Assembly & Demo

1 useful 3d print for vacuum cleaner

Vacuum bags for 3D printer filament

Dyson Cyclone Mod for Roomba S9 - Short 1

Testing 3D Printed Water Pump Impellers - Which One Performs the Best?

Clean your 3D printer Fans with this Mini Vac + Blower... Or....

👍👍👍REVERSE ENGINEERING with 3D PRINTING -Vacuum Cleaner Impeller- modelling, Solid Edge, BISSELL...

I 3D Printed a TURBINE and Produce Electricity With It.

Testing Different Water Pump IMPELLERS - Which One PERFORMS THE BEST? [REMAKE]

Dyson Powered Cyclone Separator Vacuum

DIY Impeller/ Redesigning the Impeller

3D Printing New Impeller for my Air Pump #shorts

Pneumatic Vacuum Cleaner | DIY HomeMade

Double Impeller Centrifugal Water Pump - FULLY 3D PRINTED

Комментарии

0:11:13

0:11:13

0:14:08

0:14:08

0:10:57

0:10:57

0:11:42

0:11:42

0:06:26

0:06:26

0:19:39

0:19:39

0:08:21

0:08:21

0:14:39

0:14:39

0:05:14

0:05:14

0:00:57

0:00:57

0:04:28

0:04:28

0:02:42

0:02:42

0:00:51

0:00:51

0:00:21

0:00:21

0:09:14

0:09:14

0:00:59

0:00:59

0:03:13

0:03:13

0:10:38

0:10:38

0:14:43

0:14:43

0:16:01

0:16:01

0:03:43

0:03:43

0:00:12

0:00:12

0:09:03

0:09:03

0:06:45

0:06:45