filmov

tv

How to Size, Wire, and Program a VFD to Convert Single Phase Power Into 3 Phase Power

Показать описание

In this video, I discuss how to use a variable frequency drive (or VFD) to convert single-phase power into three-phase power. I cover some important things to consider before starting your project that will help you avoid a mistake that I made. (These are applicable regardless of the brand of drive you use.) I also show you how I wired everything up and programmed my Huanyang “HY” series VFD. Trying to decipher the instruction manual that it came with was a challenge. I had to watch a lot of YouTube videos and confer with some of the electrical professionals where I work to get it figured out. So, I wanted to make this video to share what I’ve learned to help others who are trying to do the same thing.

vfd motor control, vfd drive, vfd single phase to three phase, vfd parameter setting, vfd control wiring, vfd programming, vfd connection with 3 phase motor, vfd single phase to 3 phase, vfd bridgeport mill, vfd cabinet, Haunyang, huanyang vfd setup, huanyang vfd wiring, huanyang vfd programming, huanyang vfd, huanyang, vfd 2.2kw setup, huanyang inverter setup, Huanyang VFD parameters,

Here are the links to the YouTube videos I mentioned.

Southern Ingenuity

Low Budget VFD Cabinet

capnhooks1

Setting up an Ebay VFD(Haunyang HYD02D223B) with an external switch and an external potentiometer.

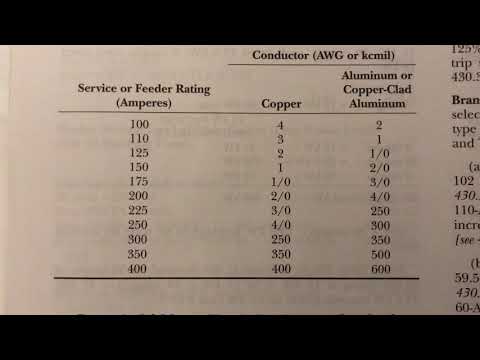

To calculate what size drive you will need, multiply the amp rating of your motor times 1.73. The proper drive should be able to output this much current or more. Check out this link for a more in-depth explanation.

The programming instructions and parameter values listed below should be compatible with any of the following HY Series drives from Huanyang: HY00D423B, HY0D7523B, HY01D523B, HY02D223B, HY03D023B, HY04D023B, HY05D523B, HY07D523B, HY001123B

Steps for programming the parameters.

1) Press “Program”

2) Press “Up” or “Down” arrows to get to the parameter you want.

3) Press “Set” to select the parameter for editing.

4) Press “Up” or “Down” arrows to enter the setting you want.

5) Press “Set” to lock in the new parameter value.

*Note: The “Shift” button changes the input position from right to left across the display.

Parameter My Explanation

Value

PD000 0 0 = Allows VFD parameters to be adjusted

1 = Prevents VFD parameters from being adjusted

PD013 0 8 = Reset VFD to factory settings

PD001 1 0 = Start/Stop motor by buttons on the front of the drive.

1 = Start/Stop motor by external switch

2 = Start/Stop motor by computer communication port"

PD002 0 0 = Motor Speed adjusted by buttons on the front of the drive

1 = Motor Speed adjusted by potentiometer (Onboard or external,

jumper on “VI” for external or “VR” for onboard)

2 = Motor Speed adjusted via computer communication port"

PD005 60 The maximum frequency that the drive will send to the motor.

PD004 60 Rated frequency of the motor as listed on the motor's nameplate.

PD003 60 The frequency (speed) the motor starts off at when PD002 is set

to 0.

PD008 208 Rated voltage of the motor as listed on the motor's nameplate.

PD014 2.0 Time in seconds for motor to accelerate to full speed.

PD015 2.0 Time in seconds for motor to decelerate to complete stop.

PD023 1 0 = Reverse motor rotation not allowed.

1 = Reverse motor rotation is allowed.

PD141 208 Rated voltage of the motor as listed on the motor's nameplate.

PD142 6.5 Full load amp rating of the motor as listed on the motor's

nameplate.

PD143 4 Number of poles = 120(f)/n where f = motor's rated operating

frequency (60Hz in the USA) and n = motor's rated RPM on the

nameplate.

PD144 1700 Rated RPM of the motor as listed on the motor's nameplate.

vfd motor control, vfd drive, vfd single phase to three phase, vfd parameter setting, vfd control wiring, vfd programming, vfd connection with 3 phase motor, vfd single phase to 3 phase, vfd bridgeport mill, vfd cabinet, Haunyang, huanyang vfd setup, huanyang vfd wiring, huanyang vfd programming, huanyang vfd, huanyang, vfd 2.2kw setup, huanyang inverter setup, Huanyang VFD parameters,

Here are the links to the YouTube videos I mentioned.

Southern Ingenuity

Low Budget VFD Cabinet

capnhooks1

Setting up an Ebay VFD(Haunyang HYD02D223B) with an external switch and an external potentiometer.

To calculate what size drive you will need, multiply the amp rating of your motor times 1.73. The proper drive should be able to output this much current or more. Check out this link for a more in-depth explanation.

The programming instructions and parameter values listed below should be compatible with any of the following HY Series drives from Huanyang: HY00D423B, HY0D7523B, HY01D523B, HY02D223B, HY03D023B, HY04D023B, HY05D523B, HY07D523B, HY001123B

Steps for programming the parameters.

1) Press “Program”

2) Press “Up” or “Down” arrows to get to the parameter you want.

3) Press “Set” to select the parameter for editing.

4) Press “Up” or “Down” arrows to enter the setting you want.

5) Press “Set” to lock in the new parameter value.

*Note: The “Shift” button changes the input position from right to left across the display.

Parameter My Explanation

Value

PD000 0 0 = Allows VFD parameters to be adjusted

1 = Prevents VFD parameters from being adjusted

PD013 0 8 = Reset VFD to factory settings

PD001 1 0 = Start/Stop motor by buttons on the front of the drive.

1 = Start/Stop motor by external switch

2 = Start/Stop motor by computer communication port"

PD002 0 0 = Motor Speed adjusted by buttons on the front of the drive

1 = Motor Speed adjusted by potentiometer (Onboard or external,

jumper on “VI” for external or “VR” for onboard)

2 = Motor Speed adjusted via computer communication port"

PD005 60 The maximum frequency that the drive will send to the motor.

PD004 60 Rated frequency of the motor as listed on the motor's nameplate.

PD003 60 The frequency (speed) the motor starts off at when PD002 is set

to 0.

PD008 208 Rated voltage of the motor as listed on the motor's nameplate.

PD014 2.0 Time in seconds for motor to accelerate to full speed.

PD015 2.0 Time in seconds for motor to decelerate to complete stop.

PD023 1 0 = Reverse motor rotation not allowed.

1 = Reverse motor rotation is allowed.

PD141 208 Rated voltage of the motor as listed on the motor's nameplate.

PD142 6.5 Full load amp rating of the motor as listed on the motor's

nameplate.

PD143 4 Number of poles = 120(f)/n where f = motor's rated operating

frequency (60Hz in the USA) and n = motor's rated RPM on the

nameplate.

PD144 1700 Rated RPM of the motor as listed on the motor's nameplate.

Комментарии

0:04:52

0:04:52

0:10:10

0:10:10

0:11:47

0:11:47

0:08:42

0:08:42

0:05:59

0:05:59

0:07:26

0:07:26

0:14:48

0:14:48

0:26:04

0:26:04

0:07:15

0:07:15

0:04:33

0:04:33

0:03:29

0:03:29

0:02:07

0:02:07

0:09:14

0:09:14

0:05:52

0:05:52

0:11:40

0:11:40

0:10:28

0:10:28

0:06:54

0:06:54

0:06:42

0:06:42

0:05:50

0:05:50

0:10:35

0:10:35

0:00:59

0:00:59

0:02:00

0:02:00

0:09:01

0:09:01

0:03:05

0:03:05