filmov

tv

Why your DeWalt planer is not a jointer #planer #woodworking

Показать описание

Why your DeWalt planer is not a jointer #planer #woodworking

Why does everyone think the DeWALT planer is better?

3 Year Review: Dewalt DW735 Planer - Is It Worth It?

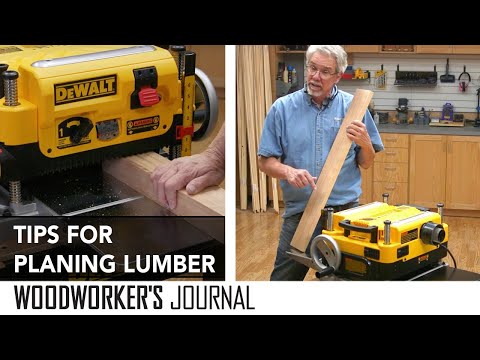

Tips for Planing Wood with the DeWalt DW735x Planer

4 Year Review of Dewalt DW735x Thickness Planer!

Dewalt Thickness Planer: An UNSPONSORED Woodworking Tool Review

Using a Planer 101

How to increase the precision of your DeWalt planer?

What a Planer Should Sound Like. Signs of a Dull Planer

Thickness Planer Tune Up and Maintenance

Unboxing My New Dewalt Planer (so simple to set up)

Is a Helical Cutter Worth It For Your DW735 Planer?

Simple maintenance on the DeWalt planer #woodworkingtools #dewalt #woodworking

Dewalt DW735 Planer Features and Review

DeWalt DW735 Thickness Planer, Good, but Harbor Freight is half the Price 🤣

DeWalt Thickness Planer!

Cheap Planer Beats Expensive With This One Thing

She's hungry!😋. Dewalt DW735 13' Planer working it's magic on freshly milled pine.

$600 vs $1,600 Planer #woodworkingtools

This is the secret to know when to change your planer blades #Planer #DIY #Woodworking

Should The Dewalt DW735 Be Your Next Planer?

How to use a Thickness Planer - DeWalt Benchtop Thickness Planer DW735 / DW735X Full Review

New upgrade to Dewalt 735 #woodworking #powertools #planer #woodshop

Using the Dewalt DW735 Planer at MakeHaven

Комментарии

0:00:26

0:00:26

0:08:35

0:08:35

0:11:26

0:11:26

0:03:21

0:03:21

0:08:14

0:08:14

0:11:01

0:11:01

0:00:55

0:00:55

0:01:00

0:01:00

0:03:48

0:03:48

0:09:57

0:09:57

0:00:56

0:00:56

0:10:41

0:10:41

0:00:33

0:00:33

0:16:07

0:16:07

0:00:15

0:00:15

0:00:14

0:00:14

0:00:58

0:00:58

0:00:14

0:00:14

0:00:50

0:00:50

0:00:18

0:00:18

0:16:47

0:16:47

0:12:29

0:12:29

0:00:24

0:00:24

0:12:40

0:12:40