filmov

tv

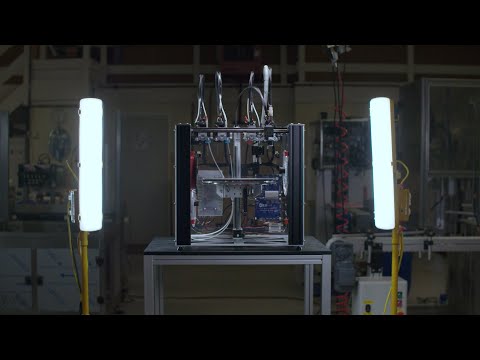

The E3D Tool Changer Is Finally Here! - Let's Review It

Показать описание

After a waiting for over a year and a half, I finally received my E3D tool changer kit in the mail. The first step to turn it into a functional printer is assembling the frame or as E3D calls it the "Motion System." In this video that's what I do.

For anyone who wants to purchase this kit, you should know that you will pay around $3500-$4000 USD, and you can't just go buy it today. I've been waiting a year and a half to get mine. You won't have to wait that long, but you do have to purchase your place in the queue for a £100 non-refundable fee that gets applied toward your purchase once your number comes up. Head over to E3D-online, and search for "Tool Changer" I'm sure you can figure it out from there.

Comments are enabled. I WILL turn them off at the first sign of trolling. I will also perma-ban your username. Leave legitimate comments only. Disagreements are acceptable, trolling/insulting is not. Have good conversations and obey proper debate etiquette.

For anyone who wants to purchase this kit, you should know that you will pay around $3500-$4000 USD, and you can't just go buy it today. I've been waiting a year and a half to get mine. You won't have to wait that long, but you do have to purchase your place in the queue for a £100 non-refundable fee that gets applied toward your purchase once your number comes up. Head over to E3D-online, and search for "Tool Changer" I'm sure you can figure it out from there.

Comments are enabled. I WILL turn them off at the first sign of trolling. I will also perma-ban your username. Leave legitimate comments only. Disagreements are acceptable, trolling/insulting is not. Have good conversations and obey proper debate etiquette.

INCREDIBLE E3D Tool Changer!

The e3D Tool Changer Does What No Other Printers Can Do, but It's Far From Perfect

E3D ToolChanger & Motion System 3D Printer Review Preview | 3D Printing Industry

The E3D Tool Changer Is Finally Here! - Let's Review It

The E3D MegaVolcano, Toolchanger and other shenanigans #MRRF2018

The E3D Toolchanger 3D Printer AND The 3-minute Sanjay Conversation #MRRF2018

Tool-Changing 3D Printer Teaser

The E3D ToolChanger & Motion System with ASMBL™ Enabled

Laser Engraving 3D Prints is GAME CHANGING! #3dprinting #diy #shorts

Building a budget, open source toolchanger - Sovol SV08 toolchanger part 1

Toolchanger in action

ProForge 300 - The ULTIMATE Tool Changer 3D Printer!

E3D Tool Changer Update - Chris's Basement

'WP-DAKSH' Voron Trident 3D Printed Tool Changer - First Look, Overview and Operation

E3D Toolchanger Live Build - Part 1 - Unboxing And Motion System Assembly

XChange: Toolchanging comes to affordable 3D printers

WP-DAKSH - Voron Trident 3D Toolchanger - 6 tools test along with cable harness

RatRig VCore3 Tool Changer - Tool Test

3D Printed Tool Changer Proof of Concept

The Wham Bam Systems MUTANT! 3D Printer Tool Changer!

DIY E3D Tool Changer - First Hemera tool change test

My 3D Printer Collection is Getting Ridiculous

Adding more tools! - Budget Sovol SV08 toolchanger part 2

The Toolchanger that ROTATES! #MRRF2022

Комментарии

0:19:34

0:19:34

0:52:18

0:52:18

0:01:37

0:01:37

0:17:57

0:17:57

0:32:18

0:32:18

0:14:05

0:14:05

0:01:37

0:01:37

0:04:53

0:04:53

0:00:40

0:00:40

0:15:25

0:15:25

0:00:45

0:00:45

0:02:43

0:02:43

0:08:47

0:08:47

0:10:12

0:10:12

1:54:35

1:54:35

0:14:07

0:14:07

0:01:55

0:01:55

0:00:22

0:00:22

0:01:30

0:01:30

0:14:39

0:14:39

0:00:13

0:00:13

0:17:44

0:17:44

0:21:35

0:21:35

0:04:41

0:04:41