filmov

tv

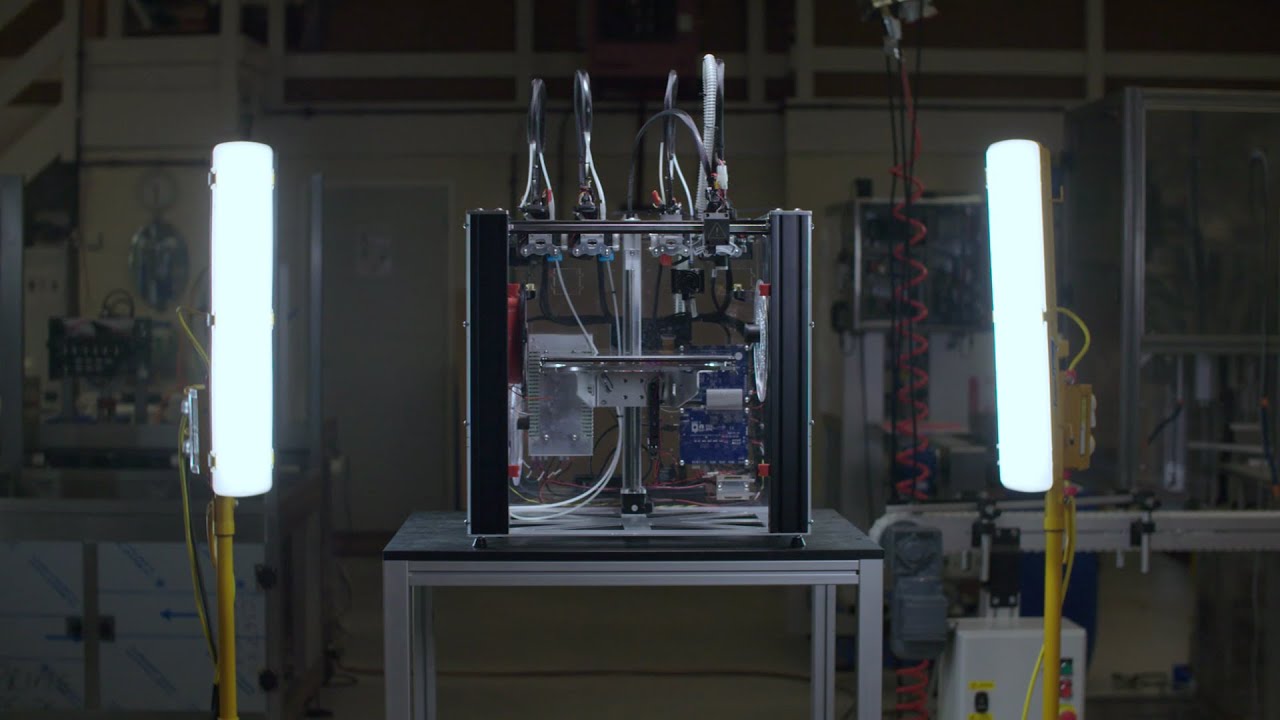

The E3D ToolChanger & Motion System with ASMBL™ Enabled

Показать описание

Through our research and development in exploiting tool-changing we have developed the capability to enhance the FDM process with subtractive machining.

Introducing the future of Desktop 3D Printing: Additive Subtractive Manufacturing By Layer.

Read our blog on ASMBL:

Purchase a ToolChanger and Motion System here -

Introducing the future of Desktop 3D Printing: Additive Subtractive Manufacturing By Layer.

Read our blog on ASMBL:

Purchase a ToolChanger and Motion System here -

E3D ToolChanger & Motion System 3D Printer Review Preview | 3D Printing Industry

The E3D Tool Changer Is Finally Here! - Let's Review It

The E3D ToolChanger & Motion System with ASMBL™ Enabled

E3D Toolchanger Pt4 - Hemera Bowden Tool Intricacies

DIY E3D Motion System - First Test

The e3D Tool Changer Does What No Other Printers Can Do, but It's Far From Perfect

The E3D MegaVolcano, Toolchanger and other shenanigans #MRRF2018

The E3D Toolchanger 3D Printer AND The 3-minute Sanjay Conversation #MRRF2018

E3D Toolchanger Live Build - Part 1 - Unboxing And Motion System Assembly

Ever Wondered How a ToolChanger Calibrates?

DIY E3D Tool Changer - First Toolchanging Test

E3D Toolchanger Pt1 - Unboxing A Masterpiece

DIY E3D Tool Changer - New brush design and prime macro

E3D Toolchanger - Assembly #01 - The Motionsystem

E3D Toolchanger Part 1

E3D ToolChanger Live Stream Part 6: Motion System Electronics

DIY E3D Tool Changer - First Test

CHANGER - a picture story of a complex Toolchanger, 3D-printer and multipurpose R&D-System

My 14-material tool changer preview: colorful 3D printing

Just upgraded my Open5X E3D tool-changer with @BrendonBuilds’s rotary bed design⚙️ more to come!...

Patent problem on 3D printer tool changer

DIY E3D Tool Changer - First Print

new brush routine for the E3D Toolchanger!

E3D ToolChanger Live Stream Part 2: Motion System Assembly

Комментарии

0:01:37

0:01:37

0:17:57

0:17:57

0:04:53

0:04:53

0:37:10

0:37:10

0:00:18

0:00:18

0:52:18

0:52:18

0:32:18

0:32:18

0:14:05

0:14:05

1:54:35

1:54:35

0:01:23

0:01:23

0:00:13

0:00:13

0:08:25

0:08:25

0:00:21

0:00:21

0:18:52

0:18:52

0:00:26

0:00:26

5:45:53

5:45:53

0:00:12

0:00:12

0:09:06

0:09:06

0:00:50

0:00:50

0:00:29

0:00:29

0:01:00

0:01:00

0:00:31

0:00:31

0:00:36

0:00:36

1:11:57

1:11:57