filmov

tv

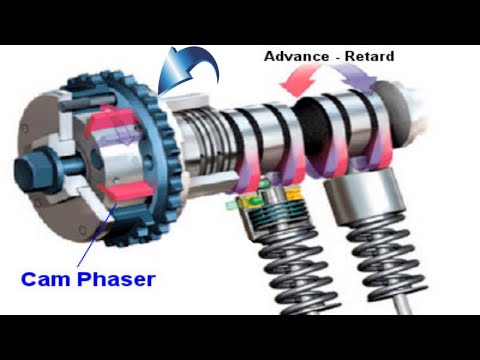

Cam phaser, camshaft, lifters, broken rocker arms on rear Bank 1 head. 3.6 V6 Pentastar P0340 P000B

Показать описание

This is part 2 of my Valve Train 3.6 Pentastar parts replacements on Bank 1 (rear/right cylinder head)

In this video I go over steps you should use if you was replacing any valve train parts on the 3.6 pentastar V6 engine.

Camshaft Bearing Cap - M6 T30 10 N.m 84 In.Lbs

Cylinder Head Cover - M6 Bolts 12 N.m 106 In.Lbs

Intake Manifold (Upper) M6 Bolts 10 N.m 89 In.Lbs

Intake Manifold (Lower) M6 Bolts 12 N.m 106 In.Lbs

Oil Control Valve/Cam Phaser M18 160 N.m 118 Ft.Lbs

In this video I go over steps you should use if you was replacing any valve train parts on the 3.6 pentastar V6 engine.

Camshaft Bearing Cap - M6 T30 10 N.m 84 In.Lbs

Cylinder Head Cover - M6 Bolts 12 N.m 106 In.Lbs

Intake Manifold (Upper) M6 Bolts 10 N.m 89 In.Lbs

Intake Manifold (Lower) M6 Bolts 12 N.m 106 In.Lbs

Oil Control Valve/Cam Phaser M18 160 N.m 118 Ft.Lbs

Cam phaser, camshaft, lifters, broken rocker arms on rear Bank 1 head. 3.6 V6 Pentastar P0340 P000B

VVT Cam Phasers. NO SPECIAL TOOLS NEEDED. Broken rocker arms, lifters, camshaft, 3.6 Pentastar tick

How to tell if your Lifters bad.How to tell if your VVT Cam Phaser Bad. 3.6 Pentastar V6 P0340 C121C

GM 3.6L V6 cam phaser failure & diagnostic

2022 Chrysler Pacifica Broken camshaft phaser.

This cam phaser was broke.

Top signs your Camshaft VVT Cam Phaser, cam sensor, oil control valve going bad. P000B P0340 P219B.

How to tell if you have bad cam phasers

How to replace a CAMSHAFT Cam Phaser 3.6 Pentastar V6 Problems ticking noise rocker arm noise

Broken cam phaser pin.....HELP!

Early Cam Phaser Failure Vs Advanced Failure - Flood Mode To Help - Let's Mash Up My Videos

How to Replace The Lifters and Camshaft on a 2013 Dodge Ram 5.7 Hemi (Every Step in 30 Minutes!)

Audi A3, S3 GTI Golf R, Engine knocking sound - Camshaft oil actuator

How to Replace a CAMSHAFT, CAM Phaser, rocker arms, 3.6 Pentastar, Timing Chain TOOLS P219A P219B

Ford 3.5L Ecoboost Cam Phaser Rattle/ The noise, The cause, The fix

5 Symptoms of Bad Cam Phasers. Causes & Replacement Cost

Camshaft & CVVT Removal & Replacement - Nu Engine - KIA & Hyundai 4 Cylinder Engines Wit...

CRITICAL Lesson For The Home Engine Builder- MORE Camshaft QC Issues To Wreck Your Day

2011 Chevy Traverse valve train inspection 3.6L V6 LLT VVT

2018 Ford F-150 cam phaser rattle after new phasers installed by dealer after 11k miles.

Ford 4.6l 3v & 5.4L 3v Camshaft Phaser Knocking Noise Fix

3.6 Pentastar V6 Problems. The Valve Train Noises. Broken rocker arm lifter cam phaser noises

Gen 3 hemi lifter and cam problems ?

How to replace a GM 3.6 VVT cam phaser without removing the timing chain or cover.

Комментарии

0:10:16

0:10:16

0:09:30

0:09:30

0:08:29

0:08:29

0:02:10

0:02:10

0:00:09

0:00:09

0:00:59

0:00:59

0:08:55

0:08:55

0:00:25

0:00:25

0:07:30

0:07:30

0:00:34

0:00:34

0:07:12

0:07:12

0:32:43

0:32:43

0:00:17

0:00:17

0:12:57

0:12:57

0:07:31

0:07:31

0:03:31

0:03:31

0:04:12

0:04:12

0:10:01

0:10:01

0:04:33

0:04:33

0:00:36

0:00:36

0:25:11

0:25:11

0:11:17

0:11:17

0:02:02

0:02:02

0:09:37

0:09:37