filmov

tv

Transitioning to the Digital Factory at Lockheed Martin Aeronautics

Показать описание

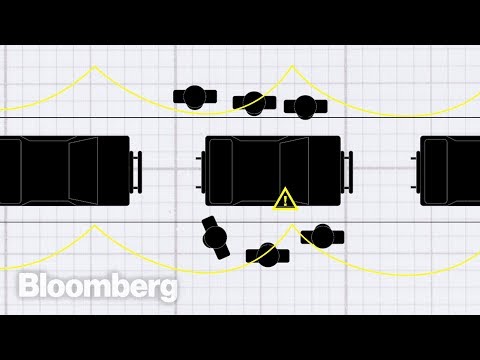

The industrial Internet of Things (IIoT) is transforming the manufacturing landscape. Lockheed Martin Aeronautics is harnessing this revolution by connecting machine assets to sensors to capture, store, and analyze critical operational detail on the F-35 production line that will enable edge analytics, condition-based maintenance, and predictive modeling. Critical machinery must be kept working synchronously to maximize throughput. Unplanned stoppage can be reduced by forecasting emerging disruption events and arranging maintenance to meet operational requirements. Improvements here can lead to cost savings and efficiencies, on time delivery, higher quality, and increased production rates. All of this culminates in lower average aircraft unit cost for the F-35. Come learn how Lockheed Martin Aeronautics is securely capturing machine data and streaming this information into a data lake and we will also take a deep-dive into an LSTM (Long Short-Term Memory) recursive neural network model that we’ve implemented for automated anomaly detection in the time-series data. These efforts are key enablers for this transformation into Industry 4.0, i.e. the connected factory.

0:36:59

0:36:59

0:01:02

0:01:02

0:01:55

0:01:55

1:03:38

1:03:38

0:01:56

0:01:56

0:04:22

0:04:22

0:03:18

0:03:18

0:47:58

0:47:58

0:02:32

0:02:32

0:15:25

0:15:25

0:12:15

0:12:15

0:05:27

0:05:27

0:44:31

0:44:31

0:20:14

0:20:14

0:03:29

0:03:29

0:59:58

0:59:58

0:00:35

0:00:35

0:02:11

0:02:11

1:04:11

1:04:11

0:01:04

0:01:04

0:04:52

0:04:52

0:06:03

0:06:03

0:41:10

0:41:10

0:21:03

0:21:03