filmov

tv

Working of Reciprocating Air Compressor Explain with Animation.

Показать описание

#ReciprocatingAirCompressor

#AirCompressor

Working of Reciprocating Air Compressor Explain with Animation

A reciprocating compressor or piston compressor is a positive-displacement compressor that uses pistons driven by a crankshaft to deliver gases at high pressure.

The intake gas enters the suction manifold, then flows into the compression cylinder where it gets compressed by a piston driven in a reciprocating motion via a crankshaft, and is then discharged. Applications include oil refineries, gas pipelines, chemical plants, natural gas processing plants and refrigeration plants. One specialty application is the blowing of plastic bottles made of polyethylene terephthalate (PET).

In the ionic liquid piston compressor many seals and bearings were removed in the design as the ionic liquid does not mix with the gas. Service life is about 10 times longer than a regular diaphragm compressor with reduced maintenance during use, energy costs are reduced by as much as 20%. The heat exchangers that are used in a normal piston compressor are removed as the heat is removed in the cylinder itself where it is generated. Almost 100% of the energy going into the process is being used with little energy wasted as reject heat.

#AirCompressor

Working of Reciprocating Air Compressor Explain with Animation

A reciprocating compressor or piston compressor is a positive-displacement compressor that uses pistons driven by a crankshaft to deliver gases at high pressure.

The intake gas enters the suction manifold, then flows into the compression cylinder where it gets compressed by a piston driven in a reciprocating motion via a crankshaft, and is then discharged. Applications include oil refineries, gas pipelines, chemical plants, natural gas processing plants and refrigeration plants. One specialty application is the blowing of plastic bottles made of polyethylene terephthalate (PET).

In the ionic liquid piston compressor many seals and bearings were removed in the design as the ionic liquid does not mix with the gas. Service life is about 10 times longer than a regular diaphragm compressor with reduced maintenance during use, energy costs are reduced by as much as 20%. The heat exchangers that are used in a normal piston compressor are removed as the heat is removed in the cylinder itself where it is generated. Almost 100% of the energy going into the process is being used with little energy wasted as reject heat.

Working of Reciprocating Air Compressor Explain with Animation.

Reciprocating Compressor C series - animation | Howden

How does an Air Compressor work? (Compressor Types) - Tutorial Pneumatics

How Air Compressors Work! (Piston Design)

Construction of Reciprocating Air Compressor

How Reciprocating Piston Air Compressors Work

Working of Reciprocating air compressor | Technical N Fit

Animation GE #Reciprocating #Compressor #Principle #Parts #working #Operation #GasTurbine

The Basics of Reciprocating Compressor for Refrigerator|How Refrigerator Compressor Works

All Types Of Compressor And Working Explained || How Does An Compressor Works?

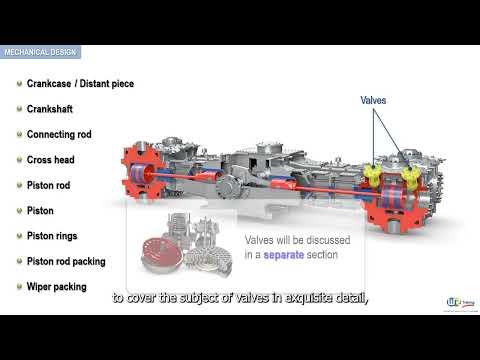

What are the mechanical components of reciprocating compressors ? Rotating Equipment by WR Training

Working of Reciprocating Air Compressor

Single stage Reciprocating compressor without clearance

reciprocating compressor working animation - maintenance

Reciprocating Compressor | Working animation Video | #education #compressor #mechanicalengineering

How it Works: A Look Inside an Ariel Reciprocating Compressor

Rotary Screw VS Reciprocating Air Compressors | CompressedAirUSA.com

Reciprocating air compressor animation

Cross Head of Reciprocating compressors

Work of Reciprocating air compressor

Reciprocating Compressor Cooling System

Single stage reciprocating air compressor working explained

How do Reciprocating Air Compressors Work? | Skill-Lync

Derivation of work required to drive the single stage Reciprocating air compressor

Комментарии

0:01:48

0:01:48

0:03:12

0:03:12

0:04:14

0:04:14

0:06:18

0:06:18

0:07:54

0:07:54

0:01:22

0:01:22

0:03:06

0:03:06

0:02:26

0:02:26

0:02:50

0:02:50

0:07:19

0:07:19

0:02:17

0:02:17

0:10:47

0:10:47

0:14:37

0:14:37

0:03:37

0:03:37

0:02:41

0:02:41

0:01:58

0:01:58

0:02:47

0:02:47

0:00:21

0:00:21

0:00:45

0:00:45

0:00:17

0:00:17

0:07:18

0:07:18

0:04:02

0:04:02

0:05:10

0:05:10

0:10:27

0:10:27