filmov

tv

Important workbench maintenance tasks you should be doing

Показать описание

How to make your woodworking bench last for generations

More workbench resources►

When you use this link to visit our sponsor, you support us►

Follow us on social media►

More workbench resources►

When you use this link to visit our sponsor, you support us►

Follow us on social media►

Important workbench maintenance tasks you should be doing

Update 20 - Workbench refresh and completion of long deferred tasks

Review P97-12 Operation and Maintenance Vehicle Room Inspection Workbench 2024

Workbench Tools, Tweaks and Diagnostics - by LemonAmiga.com

Industrial Multifunctional workbench

Refresh Your Workbench

The Most Impressive Workbench I Have Ever Seen

Availability Workbench Demo AvSim & RCMCost

15 Easy Workbench Improvements | Upgrading The Garage Workbench | Adding Storage

DSI Workbench - Troubleshooting Using Historical Data Presentation

Weekend Workbench Teaser

SAP Asset Information Workbench by Utopia - Software Demo

10 Project Management Terms You Need to Know

10 Home Bike Shop Upgrades that aren't Wrenches

Minecraft Ultimate Every Workbench Guide

ServiceNow Change Advisory Board (CAB) Workbench Overview

Will a cheap 2X6 pine workbench last?

12 Common Bike Maintenance Mistakes And How To Avoid Them

From The Workbench with Doug - Multi-Needle Maintenance

Best Workbench Ever??

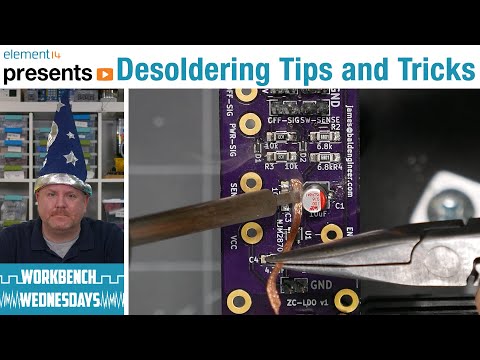

Desoldering Wick Tips and Tricks with Superwick™ - Workbench Wednesdays

10 New Amazing Kreg Tools for Woodworking

Bill Keeter (Consultant / Trainer) - Intro to Availability Workbench

How important is a drill press? I mean, it's such a boring tool.

Комментарии

0:07:56

0:07:56

0:02:58

0:02:58

0:35:54

0:35:54

0:00:26

0:00:26

0:04:45

0:04:45

0:18:35

0:18:35

1:00:25

1:00:25

0:11:17

0:11:17

0:08:31

0:08:31

0:01:31

0:01:31

0:06:25

0:06:25

0:13:57

0:13:57

0:11:07

0:11:07

0:08:42

0:08:42

0:08:08

0:08:08

0:08:00

0:08:00

0:12:21

0:12:21

0:08:47

0:08:47

0:06:50

0:06:50

0:10:47

0:10:47

0:09:01

0:09:01

0:15:53

0:15:53

0:06:18

0:06:18