filmov

tv

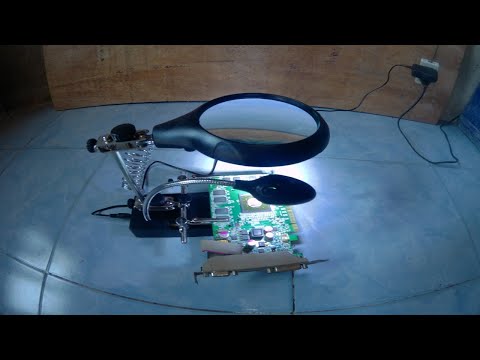

DIY Helping Hand (Third Hand) - Build Video

Показать описание

In this video I will show you how I made my own DIY Helping Hand (Third Hand) using a door stopper and flexible coolant pipes. So if you are also tired of using a cheap and crappy helping hand from the hardware store then grab some material and build your own. The build can be done in 2 or 3 evenings and the material cost is below 20 EUR (22$).

Material list:

- 4x Shrinking tube diam. 7mm, length 15mm each (Schrumpfschlauch Durchmesser 15mm, Länge je 15mm)

- 2x Insert (3d printed) - see link below

- 2x Hexagonal plug (3d printed) - see link below

- 1x Cap (3d printed) - see link below

Links to the free STL files:

Print settings:

Insert: Layer Height 0.2mm, Infill 25%, Support: yes, Brim: no (Note: the side with the small diameter should be on the print plate)

Hexagonal plug: Layer Height 0.2mm, Infill 15%, Support: no, Brim: no

Cap: Layer Height 0.2mm, Infill 15%, Support: no, Brim: no (Note: set bottom and top layers to zero)

Special Tools:

- Forstner bit diam. 30mm

- Forstner bit diam. 20mm

- Drill press

- Disc sander

- Heat gun

- 3d printer

Camera:

Sony HDR-CX730

Microphone:

Rode NTUSB

Material list:

- 4x Shrinking tube diam. 7mm, length 15mm each (Schrumpfschlauch Durchmesser 15mm, Länge je 15mm)

- 2x Insert (3d printed) - see link below

- 2x Hexagonal plug (3d printed) - see link below

- 1x Cap (3d printed) - see link below

Links to the free STL files:

Print settings:

Insert: Layer Height 0.2mm, Infill 25%, Support: yes, Brim: no (Note: the side with the small diameter should be on the print plate)

Hexagonal plug: Layer Height 0.2mm, Infill 15%, Support: no, Brim: no

Cap: Layer Height 0.2mm, Infill 15%, Support: no, Brim: no (Note: set bottom and top layers to zero)

Special Tools:

- Forstner bit diam. 30mm

- Forstner bit diam. 20mm

- Drill press

- Disc sander

- Heat gun

- 3d printer

Camera:

Sony HDR-CX730

Microphone:

Rode NTUSB

Magnetic Helping Hands, Third Hand Helping Station with 4 Soldering Helping Arms

Adam Savage's Favorite Tools: The Best Helping Hands!

Magnetic Helping Hands Soldering Third Hand with 3X & 6X LED Magnifying Lamp, Hot Air Gun Holder

NAKOOS Magnetic Helping Hands with Clamp, Vise and Lighted Magnifier

BEST DIY Solder Helping Hands (Third Hand)

How to make Third Hand tool [ Helping Hands ]

The Best Soldering Stand?

Magnetic Helping Hands Soldering Third Hand

Best Helping Hands Tool

DIY Helping Hand (Third Hand) - Build Video

Magnetic Helping Hands Third Hand Soldering Work Station |

DIY soldering helping hand

The Best Helping Hands on Amazon? QuadHands Bench Mount + Panavise Jr Reviewed!

DIY simple Helping Hand, Third Hand for Soldering

DIY helping hands

DIY Magnetic helping hands set for PCB and Electronics

DIY helping hand for soldering(third hand)

DIY Helping/Third Hand for Soldering

DIY Helping Hands Soldering Station

DIY Magnetic Third Hand For Soldering

Helping Hand Soldering Stand Magnifying Glass with LED Light PCB Holder - Unboxing & Testing

How to make a Soldering Helping Hand | DIY Soldering Station |Third Hand Tool | DIY ZONE 🇱🇰 #DIYZONE...

(Third Hand)Best DIY solder helping hand.|DIY helping soldering hand.|DIY helping hand for soldering

DIY Helping Hand ,Third Hand, Soldering Stand

Комментарии

0:00:18

0:00:18

0:06:01

0:06:01

0:00:52

0:00:52

0:07:02

0:07:02

0:02:44

0:02:44

0:03:08

0:03:08

0:07:33

0:07:33

0:04:03

0:04:03

0:05:41

0:05:41

0:12:30

0:12:30

0:00:46

0:00:46

0:02:13

0:02:13

0:13:36

0:13:36

0:01:05

0:01:05

0:15:05

0:15:05

0:11:06

0:11:06

0:06:30

0:06:30

0:08:10

0:08:10

0:05:15

0:05:15

0:02:23

0:02:23

0:07:56

0:07:56

0:04:07

0:04:07

0:06:02

0:06:02

0:08:26

0:08:26