filmov

tv

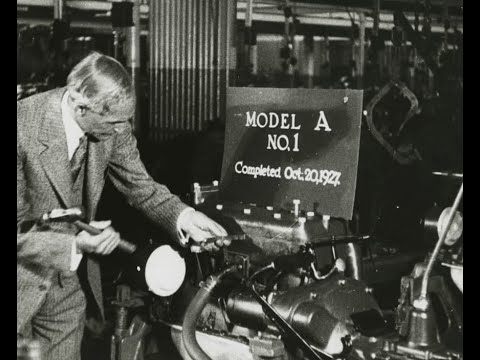

Making Model A Ford Glass; The Ford Assembly Line

Показать описание

By the time the Model A came around Henry Ford had automotive glass production mastered. Applying his moving assembly line concept to mixing, pouring, polishing, and cutting glass he was turning out millions of square feet of glass a year.

We took 11 different archive films and spliced this compilation together. It looks like most of the glass being made is door and rear window glass, there's no obvious signs of Triplex Safety Glass being manufactured in this film.

A Model A is dedicated to the history of the Model A Ford using historical images and videos as well as modern resources.

Follow us on;

Sources;

Library of Congress Ford Motion Pictures Archives

A. Nevins and F. E. Hill. Ford: Expansion and Challenge, 1915-1933, by A. Nevins and F. E. Hill

Sorensen, Charles E., and Samuel T. Williamson. My Forty Years with Ford. Wayne State University Press, 2006.

We reserve the right to moderate comments that we feel fall outside of the scope of the Model A hobby.

#1928 #1929 #1930 #1931 #fordmodela #modelaford #asmr

We took 11 different archive films and spliced this compilation together. It looks like most of the glass being made is door and rear window glass, there's no obvious signs of Triplex Safety Glass being manufactured in this film.

A Model A is dedicated to the history of the Model A Ford using historical images and videos as well as modern resources.

Follow us on;

Sources;

Library of Congress Ford Motion Pictures Archives

A. Nevins and F. E. Hill. Ford: Expansion and Challenge, 1915-1933, by A. Nevins and F. E. Hill

Sorensen, Charles E., and Samuel T. Williamson. My Forty Years with Ford. Wayne State University Press, 2006.

We reserve the right to moderate comments that we feel fall outside of the scope of the Model A hobby.

#1928 #1929 #1930 #1931 #fordmodela #modelaford #asmr

Комментарии

0:11:07

0:11:07

0:17:09

0:17:09

0:25:55

0:25:55

0:06:22

0:06:22

0:05:37

0:05:37

0:06:30

0:06:30

0:08:55

0:08:55

0:07:20

0:07:20

0:33:25

0:33:25

0:32:07

0:32:07

0:06:00

0:06:00

0:17:15

0:17:15

0:06:51

0:06:51

0:10:02

0:10:02

0:11:43

0:11:43

0:09:31

0:09:31

0:02:36

0:02:36

0:10:11

0:10:11

0:08:03

0:08:03

0:02:49

0:02:49

0:10:43

0:10:43

0:16:01

0:16:01

0:58:36

0:58:36

0:10:17

0:10:17